Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

Reference standards: ASTM D5470-2017 (Test standard for heat transfer performance of thin thermally conductive solid electrical insulation materials), MIL-I-49456A (insulation sheet, thermally conductive resin, thermally conductive glass fiber reinforcement); GB 5598-2015 (Determination method of thermal conductivity of beryllium oxide ceramics), GB/T 29313-2012 "Test method of thermal conductivity of electrical insulating materials", etc.

It is mainly used to test the thermal resistance of thin thermal conductors, solid electrical insulation materials, thermal conductive silicone grease, resin, rubber, beryllium oxide porcelain, alumina porcelain and other materials, as well as the contact thermal resistance at the solid interface and the thermal conductivity of the material. The detection material is in the form of solid sheets, and a frame can be used to detect powdery materials and paste materials. Instrument reference standards: MIL-I-49456A (insulating sheet, thermally conductive resin, thermally conductive glass fiber reinforcement); GB 5598-2015 (Method for determination of thermal conductivity of beryllium oxide ceramics); ASTM D5470-2017 (thin thermally conductive solid electrical Test Standard for Thermal Conductivity of Insulating Materials), GB/T 29313-2012 "Test Method for Thermal Conductivity of Electrical Insulating Materials", etc.

The TCT-3L heat flow thermal conductivity meter is designed and manufactured in accordance with the ASTM D5470-2017 standard. Our company has accumulated more than ten years of experience in manufacturing and user practice for this product, which has enabled the product's performance to be continuously improved and matured. It adopts servo motor to control precise automatic pressurization and automatic thickness measurement device, and is connected to a computer to achieve fully automatic control. The instrument uses 6-point temperature gradient detection to improve test accuracy. A protective thermal device (thermal protection of the sample) is added around the test rod in the test head to reduce the impact of ambient temperature on the test. It can detect thermal resistance curves under different pressures, adopt optimized mathematical models, and measure multiple parameters such as material thermal conductivity and thermal resistance, as well as contact thermal resistance at the interface. The latest technology is used to automatically compensate the cold end temperature, eliminating the need to add ice water compensation device. The latest technology is used to automatically compensate the cold end temperature, eliminating the need to add ice water compensation device.

Note:

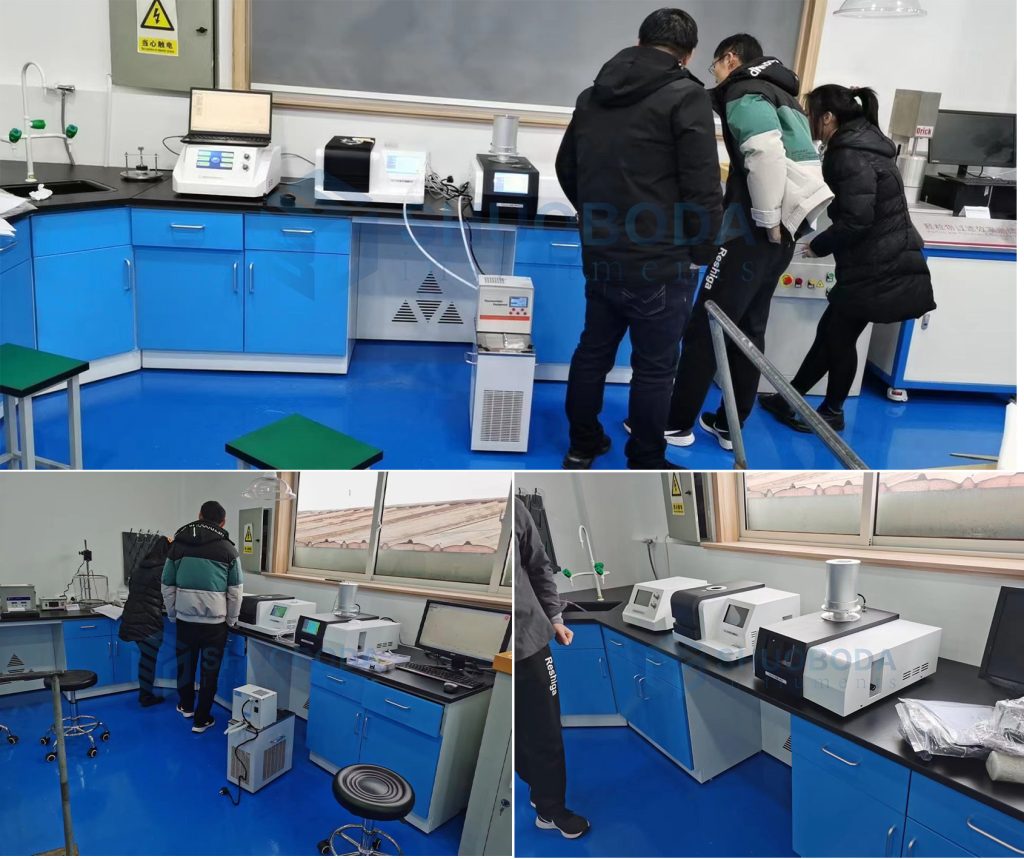

Users can choose standard or small models (with the same performance) according to the actual floor space to save laboratory space.

It is widely used in material thermal conductivity analysis and testing in colleges and universities, scientific research units, quality inspection departments and production plants.

1. Sample size: Φ30mm or 20x20mm (standard configuration), other sizes can be customized.

2. Sample thickness: 0.001~50mm (standard configuration), typical thickness: 0.02~20mm.

3. Thermal pole temperature control range: room temperature ~ 100℃ (standard configuration), temperature control accuracy 0.01℃. It can be produced according to user requirements: room temperature ~ 300°C, room temperature ~ 500°C.

4. Cold pole temperature control range: 0~99.00℃, temperature control accuracy 0.01℃ (equipped with high-precision, large-capacity low-temperature water tank).

5. Thermal conductivity test range: 0.01~50W/m.k, 0.1~300W/m.k, computer software automatically switches the range.

6. Thermal resistance test range: 0.05~0.000005m2.K/W.

7. Pressure measurement range: 0~1000N, controlled by servo motor, which can accurately set the pressure value of holding pressure, and the control accuracy is 1N.

8. Thickness measurement range: 0~50.00mm, accuracy 0.1um. Automatic thickness measurement.

9. Number of samples: 1 piece (multiple films).

10. Test accuracy: better than 3%.

11. Experimental methods: thermal resistance test of samples under different pressures, material thermal conductivity test, contact thermal resistance test, aging reliability test, material compression performance test, contact thermal resistance test between samples.

12. Computer fully automatic testing and data printout.

13. Power supply: 220V/50Hz; 500W.

1. Metal materials, stainless steel.

2. Thermal conductive silicone grease.

3. Thermal conductive silicone pad.

4. Thermal conductive engineering plastics.

5. Thermal conductive tape (the sample is very thin and sticky, and it is difficult to make a regular single sample. Use transparent plastic on one side and fix it with paper on the other side).

6. Aluminum substrate and copper clad laminate.

7. Quartz glass, composite ceramics.

8. New materials such as copper foam, graphite paper, and graphite sheets.

9. Electrical insulation materials.

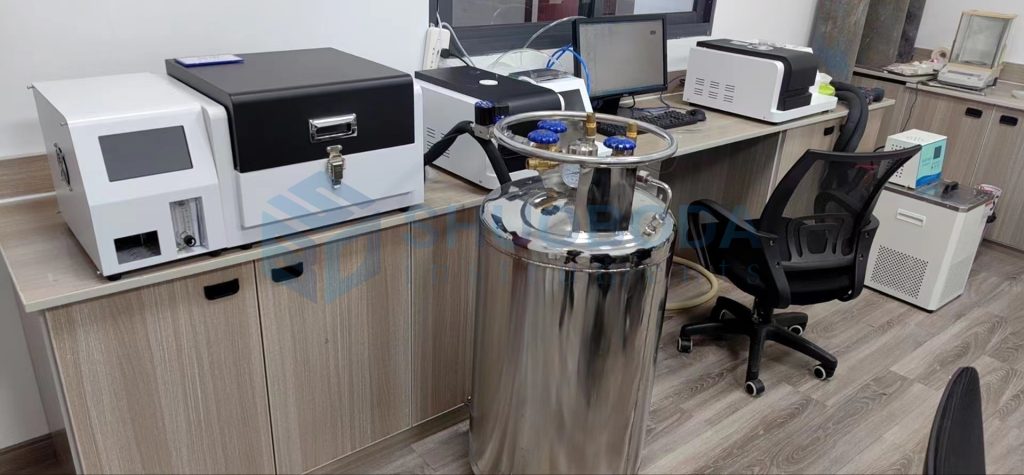

1. One host machine,

2. A set of analysis software (Chinese and English versions)

3. One precision low-temperature constant temperature water tank (temperature control accuracy 0.01℃)

4. One Lenovo computer (user can choose)

5. Two pieces of standard samples

6. A set of random accessories (a set of grease, paste and powder test boxes, and a sheet forming stamping die for convenient sampling).

1. Host: Standard floor-standing model: (length × width × height) 550 × 450 × 1550mm, net weight: 100Kg

Small desktop model: (length × width × height 500 × 400 × 780mm, net weight: 60Kg

2. Precision low-temperature constant temperature water tank: (length × width × height) 300 × 350 × 530mm, net weight: 35Kg

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us