Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

Shuoboda TCT-III multifunctional fast thermal conductivity tester mainly measures the thermal conductivity, thermal conductivity (thermal diffusion coefficient), specific heat, heat storage coefficient and thermal resistance of solids, rock and soil, powders, liquids, pastes, coatings, films, anisotropic materials, etc.

This instrument adopts the transient plane heat source method, based on the TPS transient plane heat source technology, and uses the Hot Disk probe. The advantages of this instrument are:

(1) Direct measurement of heat transfer can save a lot of time;

(2) It will not be affected by contact thermal resistance like the static method;

(3) No special sample preparation is required, only a relatively flat sample surface is required for solid materials. Different types of materials adopt different test schemes and computational mathematical models, which have the advantages of fast measurement speed, wide application range, and the ability to successfully avoid the influence of natural convection during the experiment. The actual test material range is wide, the thermal conductivity range is wide, the sample processing is simple, and the test speed is fast, which is a relatively popular test method at present.

Equipment reference standards: ISO 22007-2:2008, GB/T32064-2015.

Test materials: metal, alloy, graphite, thermal grease, silica gel, silicone rubber, ceramics, geotechnical, rock, polymer, paper, fabric, foam plastic, concrete, composite board, paper honeycomb board and other solids, powders, liquids, Thermal conductivity, thermal conductivity (thermal diffusivity) and specific heat capacity, thermal storage coefficient and thermal resistance of paste, coating, film, thermal insulation material, thermal insulation material, anisotropic material, etc.

1. Measurement range of thermal conductivity: 0.001~500 w/(m.k), resolution 0.0001w/(m.k);

2. Thermal diffusivity (temperature conductivity) range: 0.1~100 m2/s;

3. Range of heat storage coefficient: 0.1~30 w/(m2.k);

4. Range of specific heat capacity: 0.1~5 kJ/(kg.℃);

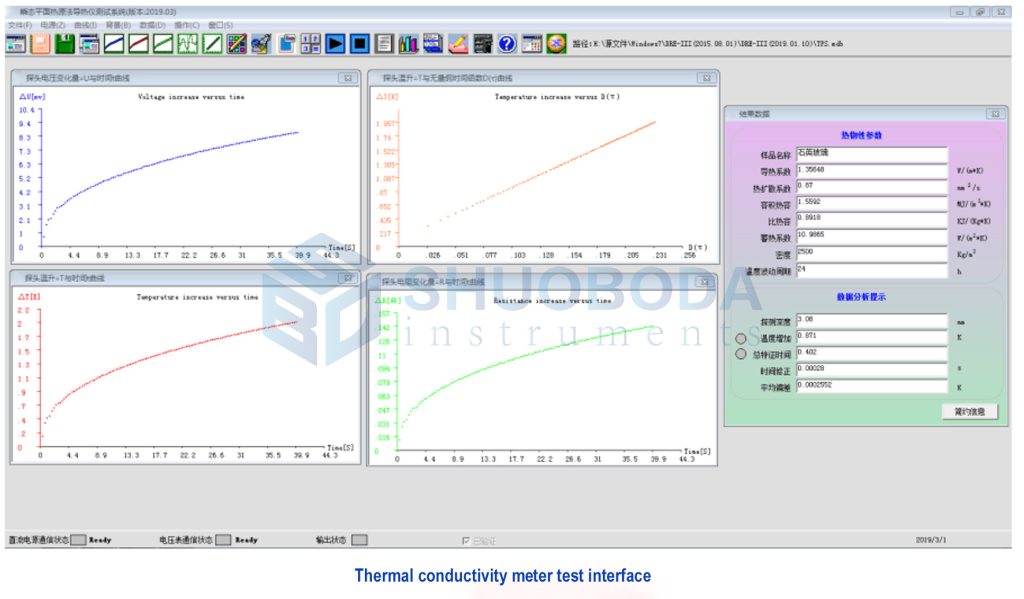

5. Thermal resistance range: 0.5~0.000005 mm2.k/w;

6. Temperature measurement accuracy: ≤0.001℃;

7. Measurement relative error: ≤3%;

8. Repeatability error: ≤ 3%;

9. Test time: 1-120 seconds.

10. Sample test ambient temperature range: -40~150℃; standard configuration: room temperature.

Various high and low temperature section control boxes (-40~150℃) or test state under vacuum state can be selected according to customer requirements, and the cost is extra according to the contract;

11. Probe configuration: standard configuration: diameter Φ15mm.

Probe diameter can be selected according to customer requirements: Φ30mm, Φ15mm, Φ7.5mm, Φ4mm or at the same time, the contract is agreed, and the cost is extra;

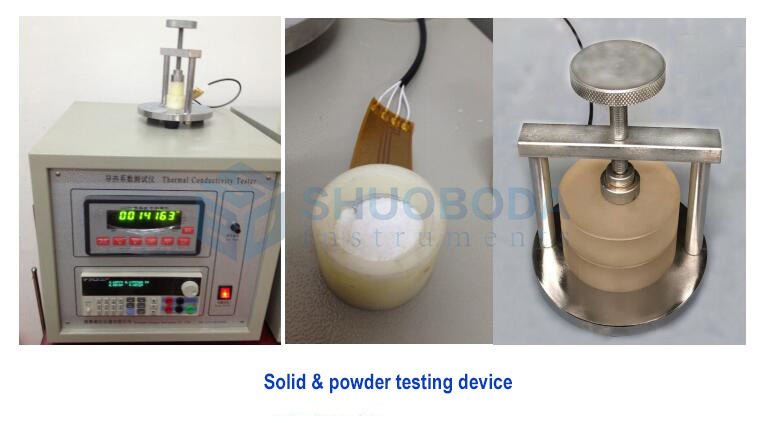

12. Test sample requirements:

a. Solid block or round, square, special-shaped samples, no special preparation is required, only a relatively flat sample surface, equipped with a special sample clamping device.

b. There are no special requirements for powdery, pasty, and liquid substances, and it is equipped with a special sample test box.

c. The measured thinner material (thickness 0.01 ~ 1mm), special test program and mathematical model for testing.

d. High conductivity materials (100~500W), special test plan and mathematical model for testing.

e. Thermal insulation materials (0.010~0.050W), special test plan and mathematical model for testing.

13. Fully automatic test software is used to quickly and accurately analyze the parameters of the test process and output the report on the sample.

14. Power supply: AC 220V±10%, 50/60 Hz, machine power: <500w;

1. Heating material: metal nickel;

2. Operating temperature: -50~150℃;

3. Maximum power: 20w;

4. Maximum voltage: 20V;

5. Maximum current: 1A;

6. Resistance: about 10Ω, according to the resistance marked on the probe;

7. Nickel wire specification: thickness 0.01mm, hot wire width: 0.35±0.03mm;

Hot wire spacing: 0.35±0.03mm;

8. Protective layer material: polyimide film (Kapton); single layer thickness: 0.06mm;

9. Probe diameter: Φ30mm, Φ15mm, Φ7.5mm.

10. The total thickness of the probe (including the thickness of the bonding layer) is 0.07±0.02mm.

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us