Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

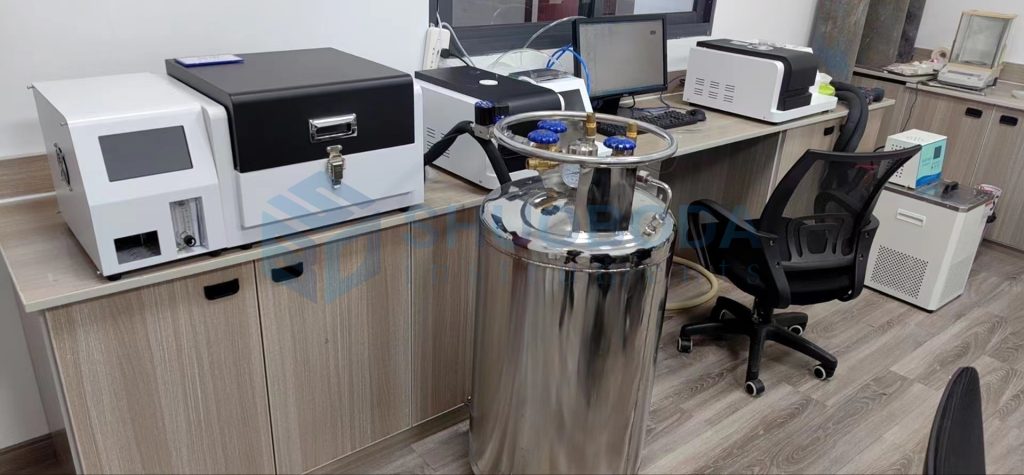

TCT-2PL thermal conductivity tester (flat plate heat flow meter method) adopts the internationally popular heat flow meter method to detect thermal conductivity and thermal resistance, and is equipped with a computer to achieve fully automatic detection and generate experimental reports. The instrument adds a stable hot surface temperature to one side of the sample, heat is transferred to the cold side (room temperature) through the sample, and the transferred heat flow is measured to calculate the thermal conductivity and thermal resistance.

This test method is simple, fast and has good repeatability. It is very suitable for research and development on heat transfer of metal materials such as profiles. It can also be used for testing plastics, rubber, graphite, insulation materials, aerogel panels, vacuum glass, etc. It is widely used in colleges and universities, scientific research institutes, quality inspection, factories and mines.

Reference standards: GB/T10295-2008 (Determination of steady-state thermal resistance and related characteristics of thermal insulation materials - heat flow meter method) and ASTM C518-04 Test method for determination of steady-state heat flux and heat transfer characteristics using the heat flow meter method.

1. Thermal conductivity range: 0.00001~10W/mk, 0.001~300W/mk.

2. Measurement accuracy: 3% (domestic heat flow meter); 1% (imported heat flow meter);

3. Sample size: 20×20~300×300 (mm). Special sizes can be customized.

4. Can test solid materials and powdery materials.

5. Measurement time is 15-20min.

6. Hot surface temperature and control: room temperature ~ 199.9°C (standard configuration), room temperature ~ 499.9°C, higher temperature can be determined according to user requirements. Flat plate heater, bidirectional thyristor control, temperature control accuracy 0.1℃

7. Cold surface temperature and control: 0~99.9℃ (standard configuration), -10~99.9℃, lower temperature can be determined according to user requirements. The cold surface is water-cooled to ensure stable temperature of the cold surface (precision constant temperature water tank with adjustable temperature), and the temperature control accuracy is 0.1°C.

8. The whole process uses computer automatic testing and printing to store experimental data.

it may be caused by loose contact between the sample and the heating element or bubbles or impurities in the sample. The solution is to adjust the pressure between the sample and the heating element or to choose a more suitable sample preparation method, such as using a powder sample.

It may be caused by a malfunction of the temperature controller or fluctuations in ambient temperature. The solution is to check whether the temperature controller is working properly or to provide better temperature control of the instrument.

It may be caused by the thermocouple being oxidized or burned out at high temperature. The solution is to regularly check whether the thermocouple is normal. If it needs to be replaced, it should be replaced with the correct tools and methods.

It may be caused by incorrect instrument settings or non-standard sample preparation. The solution is to check whether the instrument settings are correct, such as heating power, heating rate, etc., and at the same time optimize the sample preparation method to ensure that the sample is uniform, bubble-free, and defect-free.

It may be caused by power failure or unstable voltage. The solution is to check whether the power supply is normal. If the power supply needs to be replaced, a stable voltage should be used.

It may be caused by the failure of the internal mechanical parts of the instrument. The solution is to regularly check whether the internal mechanical parts of the instrument are normal. If repairs are needed, they should be repaired by professionals.

Note:

The instrument should be shut down first and safety ensured, and then preliminary inspection and troubleshooting should be carried out according to the instrument's instruction manual and operating guide. If the problem cannot be solved, you should contact professional maintenance personnel to handle it.

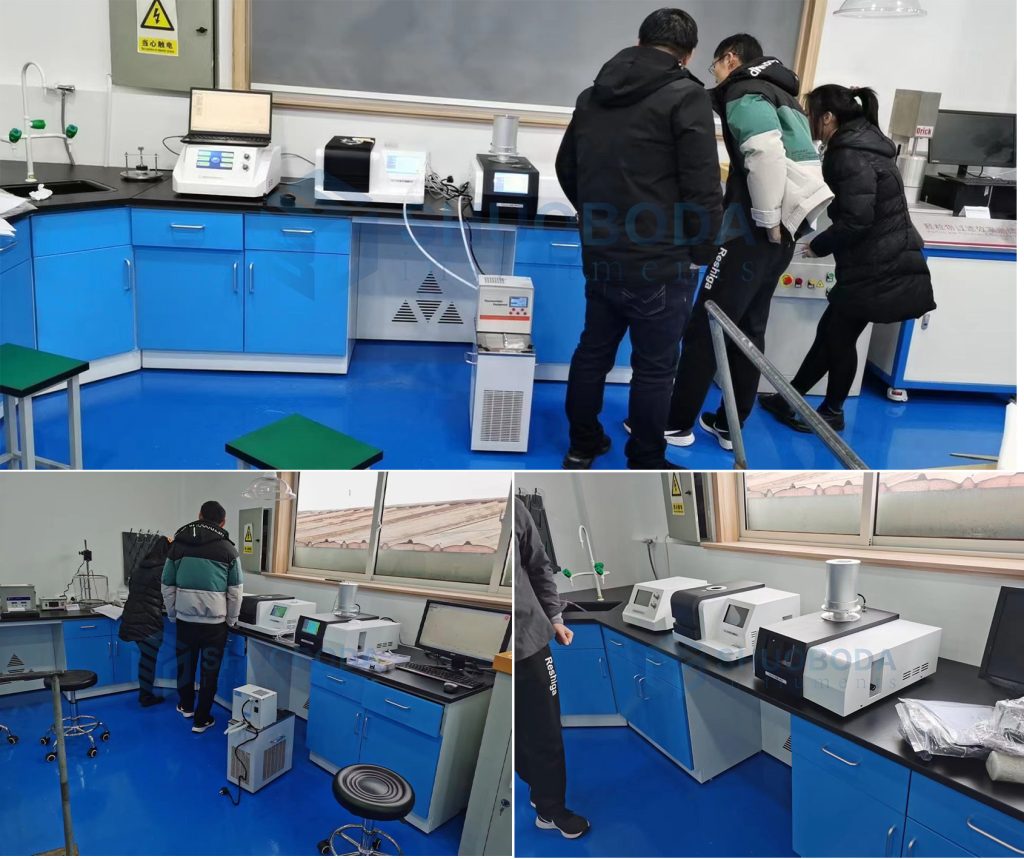

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us