Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

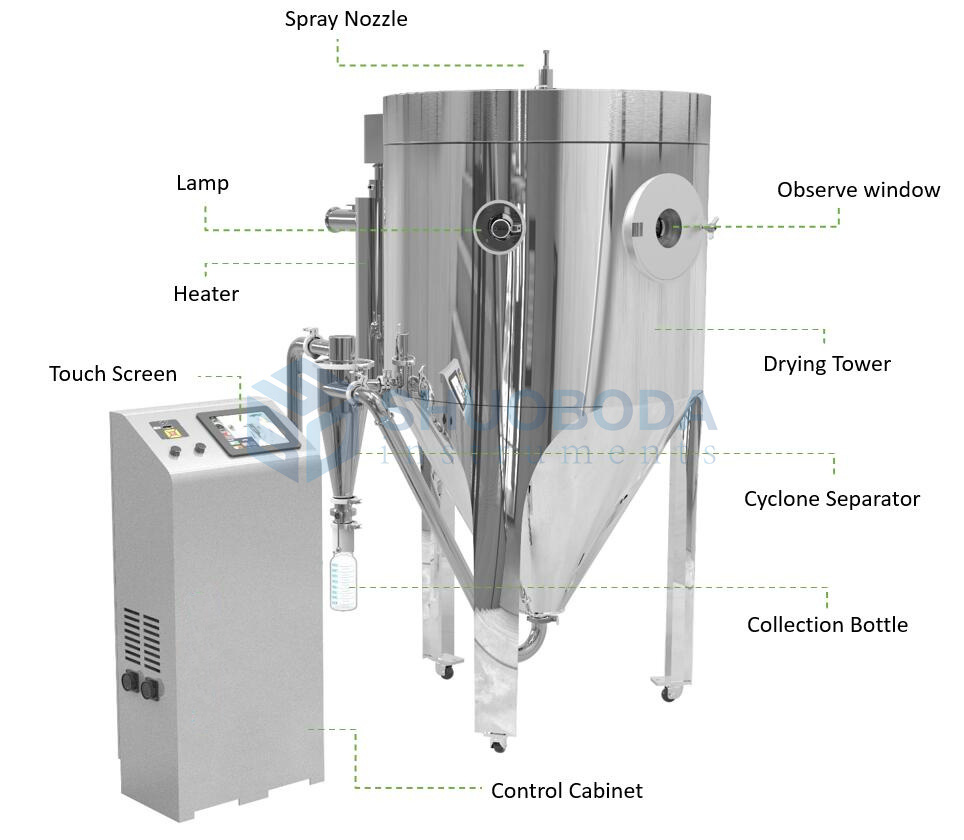

SPD-H5A advance pilot spray dryer has a stable appearance, beautiful atmosphere, convenient operation, patent shape design.

SPD-H5A Split Type Pilot Spray Drying Machine has a stable appearance, beautiful atmosphere, convenient operation, patent shape design, high quality technology level and new control system.

It meets the needs of more laboratory and pilot users, and even can replace the imported spray dryer.

SPD-H5A pilot spray dryer has been introduced to meet the still increasing demand for a more flexible, modern and easy-to-handle laboratory dryer having different levels of control systems. The sanitary design, the easy access to all internal surfaces and the range of available options for optimising the configuration will be appreciated by all users

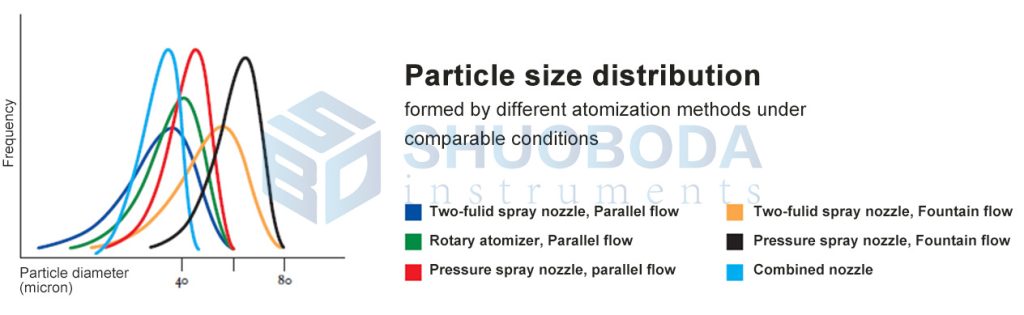

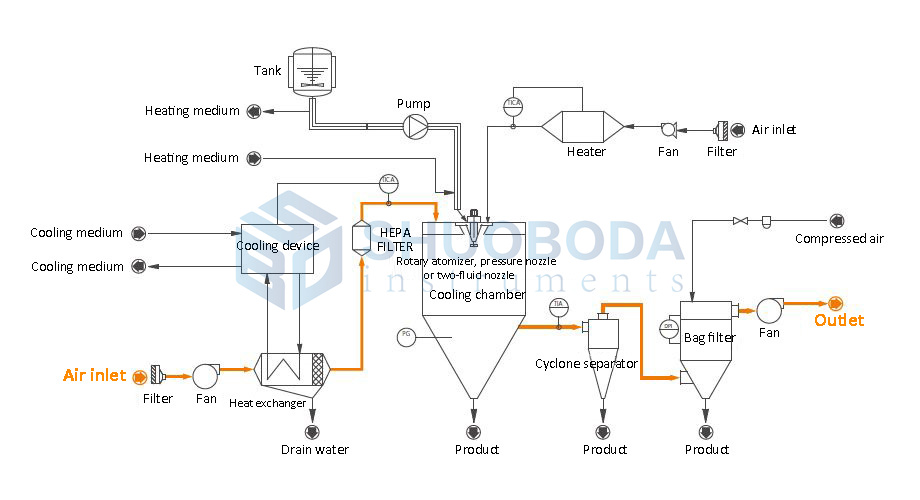

The liquid RN-Con feed is atomized by a two-fluid nozzle co-current or, alternatively, by an centrifugal atomizer.

The drying gas is heated by means of electricity, and enters the chamber via a specially LS- Adv designed gas distributor.

The drying chamber has a conical bottom with a 60゜cone angle. The chamber is provided with WD door, light and sight glass.

The plant is delivered with an PLC including necessary control and instrumentation.

Materials of Construction

Standard list:

| No. | Item Name | Specifications |

| Basic | ||

| 1. | Equipment model | SPD-H5A |

| 2. | Max. water evaporation | 5L/H |

| 3. | Peristaltic pump | 0~5000ml/h |

| 4. | Inlet air temperature | 30-300 ° C ± 2 ° C |

| 5. | Air temperature | 30-120 ° C ± 2 ° C |

| 6. | Inlet & outlet temp. sensor | PT-100 temperature sensor, intelligent PID control |

| 7. | Atomization structure | Seamless design of nozzle atomizer & rotary atomizer with RN-Con modular design |

| 8. | Atomizer | Original imported, standard parallel flow two-fluid atomizer |

| 9. | Hot air distributor | H-Adv integrated structure hot air distributor, rotating like wind, evenly distributed, adjustable wind direction |

| 10. | Door hole | WD round door hole design, beautiful appearance, both window observation and door cleaning, with thermal insulation design |

| 11. | Induced draft fan | Taiwan high pressure fan, 1.5KW/220V, frequency conversion control |

| 12. | Electric heaters | 10KW/380V, special stainless steel |

| 13. | Dry air flow | Up to 100 kg/h |

| 14. | Average drying time | 1.0-1.5s |

| 15. | Automatic draining device | Automatic needle, adjustable operating frequency 1-60s |

| 16. | Air compressor | 2.2KW, gas production 180L/min, working pressure 2-6bar |

| 17. | Capacity of collection flask | 1.5L |

| Control system | ||

| 1. | Electrical control cabinet | The chassis adopts the HSSP standard spraying process, and the elegant electrical components adopt Schneider Electric standard. |

| 2. | touch screen | 10 inch capacitive high resolution touch screen with resolution: 1024*800 |

| 3. | Software system | SD-Control 2.0 version control system with temperature, pressure sensing, pump start, stop and variable frequency control data curves, logging and alarm functions. |

| 4. | Quick release design | Temperature sensors, power supplies, and air lines are designed for quick insertion and tube management for easy maintenance and finishing |

| Others | ||

| 1. | voltage | AC380V, 50HZ |

| 2. | rated power | AC380V/16KW |

| 3. | Mini. space required (L*X*H) | 1930mm×1030mm×2010mm |

| 4. | weight | 265KG |

| Item No. | Item Name | DESCRIPTION |

| SPD5A002 | Air compressor | Silent and oil free |

| SPD5A003 | Air hammer | Air hammer system for automated control |

| SPD5A004 | Centrifugal atomizer | Rotary high speed centrifugal atomizer |

| SPD5A005 | Bag filter | Used to treat dry exhaust and recover residual materials |

| SPD5A006 | Bag filter | Used to treat dry exhaust and recover residual materials with pulse function |

| SPD5A007 | Air pre-filter | SS304 type air pre-filter rack |

| SPECIFICATIONS | VALUE |

| Power (W) | 3000 |

| Exhaust volume (L/M) | 608 |

| Noise dB(A) | 56 |

| Maximum pressure (Bar) | 8 |

| Gas tank capacity (L) | 120 |

| Gross weight (KG) | 124 |

| Net weight (KG) | 94 |

| Size (L/W/H) cm | 122*55*91 |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us