Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

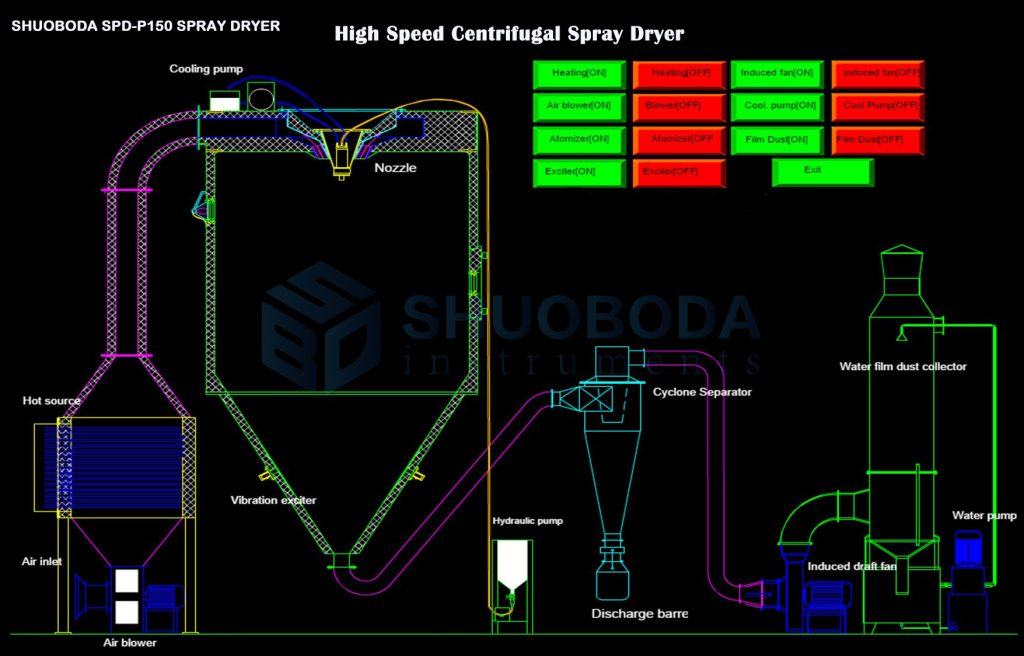

SPD-P5 spray dryer is a drying equipment suitable for the liquid material with low temperature point and high viscosity, which has been improved several times on the basis of domestic and foreign spray dryers. The working principle is: cold air is filtered through the filter, then enters the heater, is heated to a certain temperature, and then enters the air distributor at the top of the spray tower, and the hot air spirally flows to the bottom of the tower. The liquid is pumped to the centrifugal atomizer at the top of the tower body, and the liquid is torn into extremely small mist droplets. The liquid droplets and the hot air are in parallel contact, and the heat exchange is fully performed. The water content is rapidly vaporized and evaporated, and dried in a very short time as a finished product. The finished product is separated by a cyclone and discharged, and the exhaust steam is discharged by an induced draft fan.

| NO. | Item Name | Specs | Material | Qty | Remark |

| Feeding system | |||||

| 1 | Peristaltic pump | --- | --- | 1pc | P=0.55KW |

| Hot air system | |||||

| 1 | air filter | --- | Frame is SUS304 | 1 set | Primary filter |

| 2 | air filter | --- | Frame is SUS304 | 1 set | Medium effect filter |

| 3 | Electric heating | --- | SUS304 | 1 set | P=18kw |

| 4 | Hot air duct | --- | SUS304, δ1.5 | 1 set | With insulation, matt treatment |

| 5 | Pipe flange | --- | SUS 304 | --- | |

| Drying tower system | |||||

| 1 | Main tower | Diameter: φ0.8m | 304, δ2.0 | 1 set | Inner wall mirror polished, outer wall matt finish |

| 2 | Adjustable hot air distributor | --- | SUS304, δ2.0 | 1 set | mirror reflection |

| 3 | Variable spiral inlet vortex | --- | SUS304, δ3.0 | 1 set | mirror reflection |

| 4 | Electric high speed centrifugal atomizer | 1-5 | SUS304, alloy | 1 set | P=0.75kw frequency control |

| 5 | Vibrator | --- | SUS 304 | 1 pc | Manual |

| 6 | Clean up the inspection door | φ300mm | SUS 304 | 1 pc | |

| 7 | Door handle | --- | SUS 304 | 1 set | |

| Receiving system | |||||

| 1 | Primary cyclone separator | LT-280 | 304, δ2.0 | 1pc | Long cone, matt finish, with quick opening |

| 2 | Receiving bucket | --- | --- | 1pc | Transparent plastic bottle |

| 3 | Induced draft fan | 9-19-4A | Q235A | 1 set | P=2.2kw |

| 4 | Air duct | --- | 304, δ1.5 | 1 set | Matte processing |

| 5 | Exhaust pipe | --- | 304, δ1.5 | 1 set | --- |

| Control System | |||||

| 1 | Control cabinet is SUS304 stainless steel, color touch screen control (1) Inlet air temperature display, automatic control (2) Outlet temperature display (3) Feed amount control (4) Dynamic display of system operation process | --- | |||

| 2 | Nebulizer water cooling | --- | |||

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us