Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

SPD-OMINI Spray Dryer is especially for organic solvents, an inert gas medium formed by circulating nitrogen is used to replace the usual air medium for spray drying. In addition to recycled products, organic solvents can be recovered.

It is suitable for drying of heat-sensitive substances such as biological products, biological products, such as pesticides, enzyme preparations, etc. Because the sprayed materials are only exposed to high temperature when they are sprayed into mist-shaped particles, they are only heated instantly, which can keep these active materials from being damaged after drying.

| Capacity | 2000ml/h | Range | 30-250℃ | Gas | N2 |

| The maximum amount of water evaporated | 2000ml/h |

| Intake air temperature | 30~250℃(±0.5℃) |

| Outlet air temperature | 30~100℃(±0.5℃) |

| Electric heater | 3.0 KW/AC220V; Material: 2520 special stainless steel |

| Inlet and outlet air temperature monitoring | Taiwan PT-100 platinum resistor, intelligent PID control |

| Spray system | American brand atomizer, 0.7mm diameter two- fluid atomizer(Optional caliber: 0.4mm; 1.5mm) |

| * Cloth bag filter device | main material is stainless steel, built-in stainless steel folding high efficiency filter element |

| Drying time | 0.8s~1.5s |

| Feed rate | 50~2000ml/h |

| Atomizing atomizer automatic plugging device | Automatic needle frequency is adjustable, 0 ~ 60 seconds/time (manual needle function is also available) |

| Control system | Germany Siemens PLC automation control system; Imported 7 inch color touch screen |

| Oxygen measuring system detection range | 0-100% |

| Software version | Independent intellectual property rights OS 1.0, visual touch operation;Display and control the inlet air temperature, outlet air temperature, frequency conversion and needle frequency;Data recording and export, curve analysis function, alarm and overload protection |

| Oxygen detector module | Ensure that the oxygen concentration is below 3% before starting feeding (the value can be set) |

| Pressure measuring system range | 0-100Kpa |

| Explosion-proof module | Automatic pressure relief above 3Kpa (value can be set) |

| Bursting disk | Automatic type |

| Air blower | Delta variable frequency governor, imported fan, 0-70m³/h arbitrary adjustment (variable frequency fan) |

| Drying tower size | φ204*640mm(H) |

| Filter recovery size | Φ133*550mm(H) |

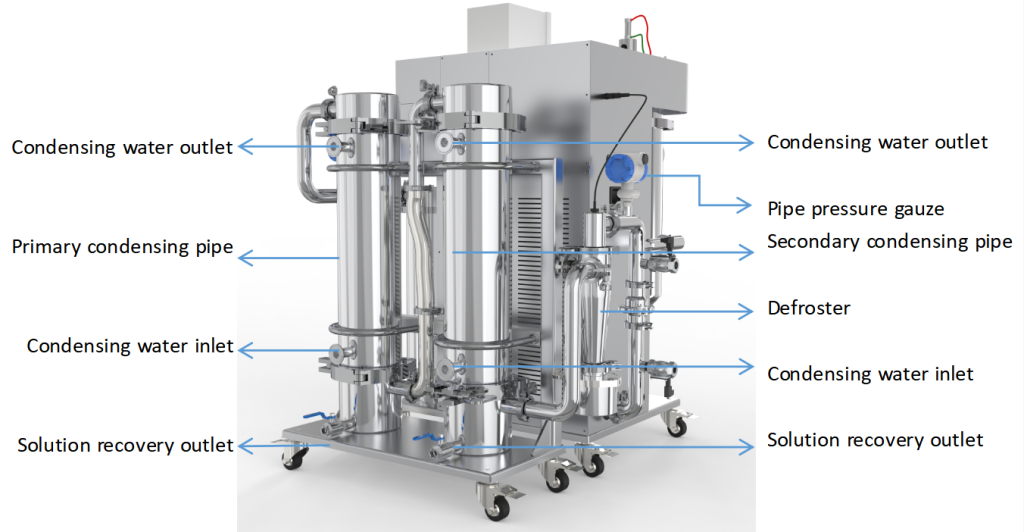

| Condensing unit size | φ159*830mm(H)X2 |

| Quick removal design | Thermometers, air lines, power supplies, all use quick-plug design |

| option | Magnetic stirrer, weighing system, etc |

| Power source | 220V;50Hz |

| Overall size | L*W*H=1000*1000*1200mm |

| Gross weight | 140KG |

| atomizer | Spray |

| Peristaltic pump | Durable |

| Air blower | Dagang |

| Fan converter | Delta |

| PLC control system | Siemens |

| PT100 temperature electrode | Twidec |

| PT100 Aviation plug | Twidec |

| Electrical components: air switch,Relays, switch buttons, etc | Schneider |

| HMI | Weinview |

| atomizer cleaner (through needle) is provided, when the atomizer is blocked, it will be automatically cleared, and the frequency of the through needle can be automatically adjusted |

| Closed nitrogen circulation, saving the amount of gas used, experimental safety, prevent sample oxidation |

| High-precision oxygen measurement system, according to the level of oxygen concentration automatically control the feed start and stop, the safety of the experiment |

| Sensitive pressure measuring system and automatic pressure relief, space pressure safety |

| The spray head is concentric and atomized to ensure that there is no eccentricity causing spray to one side of the bottle wall |

| Filter system In order to maintain the purity of the sample, the air inlet filter is equipped |

| Multi-stage porous solvent condensation system to improve solvent recovery |

| The upgraded atomization system effectively solves the problem of adhesion of some viscous materials in the cyclone separator |

| Frequency conversion fan, control the amount of air in and out, reduce the loss of fine materials |

| The drying tower vortex separator can be split and cleaned to solve the problem of difficult cleaning |

| 7 inch LCD touch screen, temperature curve memory function, real-time monitoring, the whole machine is made of stainless steel |

| Just press the stop button when shutting down, and the machine will stop running immediately except for the fan to ensure that the heating part of the equipment will not be burned out due to misoperation |

| Self-produced nitrogen generator can be selected to reduce the frequency of use of nitrogen cylinders |

| After drying, the particle size of the finished dry powder is more uniform, and more than 95% of the dry powder is in the same particle size range |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us