Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

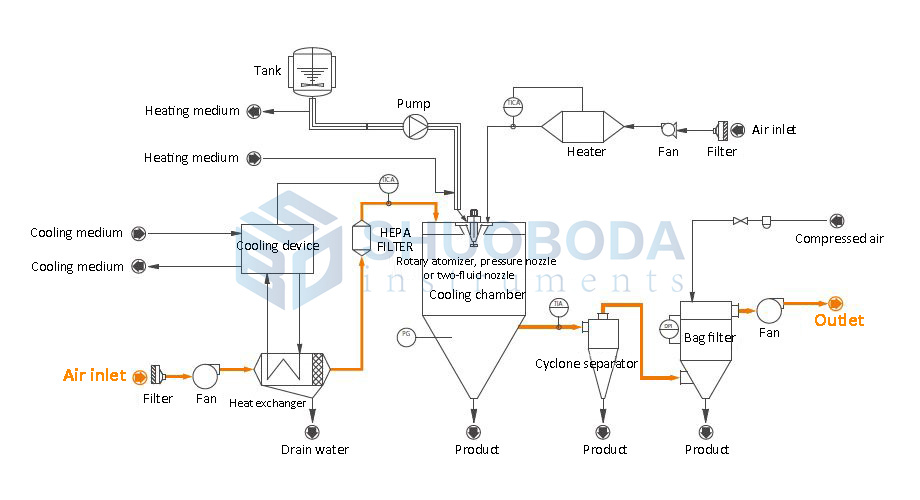

SPD-HA Series Pilot spray dryers are based on the original test spray dryer of SHUOBODA through a large number of research and learn from the Danish Niro and Anhydro spray dryer design concept, and the newly developed upgraded version of the pilot type spray dryer.

SPD-HA Series has a stable appearance, beautiful atmosphere, convenient operation, patent shape design, high quality technology level and new control system, which meets the needs of more laboratory and pilot users, and even can replace the imported spray dryer.

Technical Parameters

| No. | Item Name | Specifications |

| Basic | ||

| 1. | Equipment model | SPD-HA series |

| 2. | Max. water evaporation | 5L-30L/H |

| 3. | Peristaltic pump | 0~35L/H |

| 4. | Inlet air temperature | 30-250 ° C ± 2 ° C |

| 5. | Air temperature | 30-120 ° C ± 2 ° C |

| 6. | Inlet & outlet temp. sensor | PT-100 temperature sensor, intelligent PID control |

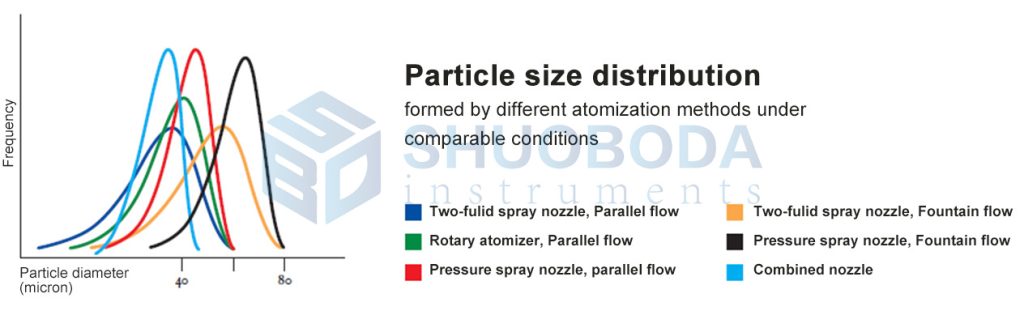

| 7. | Atomization structure | Seamless design of nozzle atomizer & rotary atomizer with RN-Con modular design |

| 8. | Atomizer | Centrifugal atomizer |

| 9. | Hot air distributor | H-Adv integrated structure hot air distributor, rotating like wind, evenly distributed, adjustable wind direction |

| 10. | Door hole | Round door hole design, beautiful appearance, both window observation and door cleaning, with thermal insulation design |

| 11. | Drift Fan | Taiwan high pressure fan, 1.5KW/220V, frequency conversion control |

| 12. | Electric heaters | 380V;Special stainless steel |

| 13. | Dry air flow | Max 100 m³/h |

| 14. | Average drying time | 1.0-1.5s |

| 15. | Automatic Remove Blockages | Automatic needle; Frequency adjustable;0~60 seconds / time |

| 16. | Air compressor | Power :0~15KW;Air :0~900L/min;Pressure:10bar |

| Control system | ||

| 1. | Control cabinet | HSSP standard spraying process Schneider electrical standard production |

| 2. | touch screen | 10 inch capacitive high resolution touch screen with resolution: 1024*800 |

| 3. | Software system | Control 2.0 version control system with temperature, pressure sensing, pump start, stop and variable frequency control data curves, logging and alarm functions. |

| 4. | Quick release design | Thermometer; Air line;Power supply |

| Others | ||

| 1. | voltage | AC380V, 50HZ |

| 2. | rated power | AC380V/0~50KW |

Scope of supply

| Feed system |

| Feed pumps Peristaltic type with silicone rubber feed tube Motor (1 x 220 V, 50 Hz) Touch screen control: 0-100% adjustable Flow rate: Min.10RPM -17mL /min; Max.390RPM -700mL/min(Based on water) |

| Atomizing system |

| Co-current two fluid nozzle atomizing system Using the American imported atomizer. Located in the top of chamber Included feed tube, compressed air tube and nozzle Compressed air flow meter Compressed air consumption: 10 bar allow to operate in high compressed air pressure. Material of nozzle pipe: AISI 316 RN-Con modular structure design, nozzle atomizer and rotary atomizer can be switched freely |

| Electrical Gas Heating System |

| Electrical Gas Heater Inlet air filter Wind speed sensor for heating protection Power:0~ 31.5 kW Max. inlet temperature: Approx. 250°C |

| Drying Chamber System |

| Drying Chamber Size :cone 60° Sanitary design WD circular door hole design, with window observation and door cleaning function, with thermal insulation design Hot air distributor adopts H-Adv integrated structure design, uniform distribution, adjustable wind direction and angle Monitoring light l Well insulated with rock wool Air hammer: 1 external interface, can use rubber hammer, also can add pneumatic hammer Chamber material : Internally AISI 304 / Externally AISI 304 The external surface is treated by stainless steel mirror technology, which is beautiful and generous. |

| Exhaust Pipe Duct connection from chamber to cyclone, easy dismantling Material: AISI 304 |

| Spare Parts Two powder glasses One inlet filter cotton |

| Exhaust and Powder Discharge System |

| Cyclone Separator Type: HCF, Size: ø650 mm Highly effective separation of powder and process gas Easy dismantling by means of a hand wheel for cleaning Powder discharge through a butterfly valve into powder glass Powder glass: 0~1000 mL Material :AISI 304 |

| Exhaust fan Imported high pressure fan, 9kW Flexible tube with cyclone Frequency control: Speed 0-100% controllable |

| Control System |

| Independent design, moveable to fit the circular design of the tower Unique painting processor using standard HSSP Siemens PLC Smart Controller Advanced touch texture screen, high colour fidelity Self-owned intellectual property Control 2.0, visual touch operation Display and control of inlet air temperature, outlet air temperature, frequency conversion, needle frequency, etc.;data record and export, curve analysis function, alarm and overload protection Bag filter automatic dust control l Automatic control of air hammer system pneumatic vibration linkage control high speed centrifugal atomizer |

| Engineering Assistance Engineering assistance in connection with the commissioning of the spray dryer for one day, board and lodging, local transportation included |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us