Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

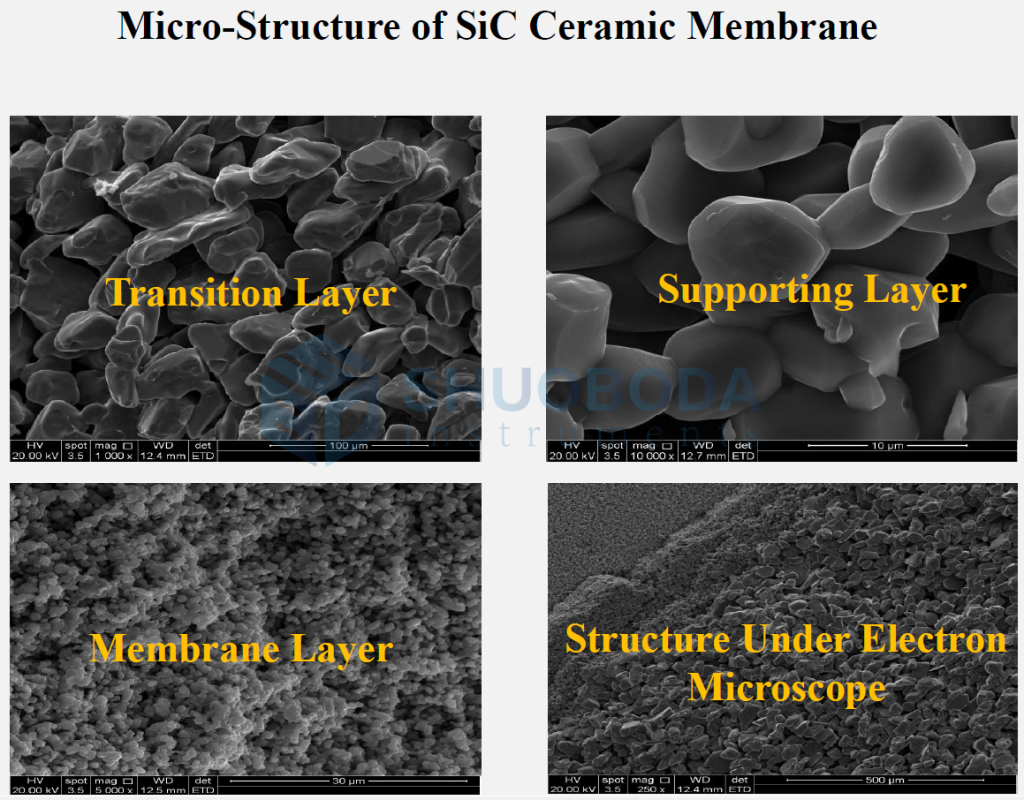

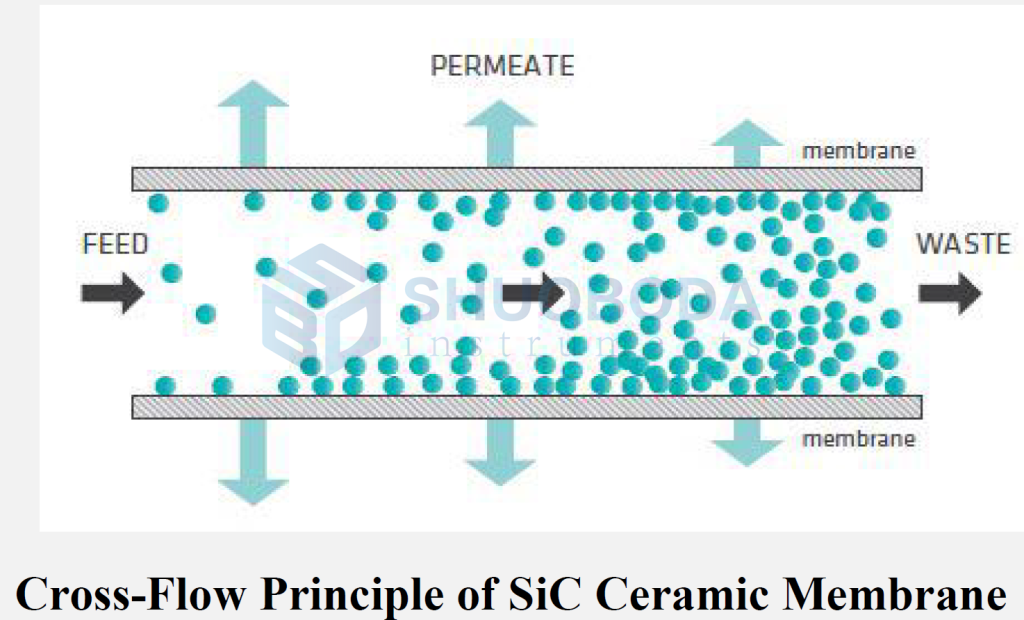

Silicon carbide membrane (SIC) is made by high-temperature sintering using recrystallization technology. Its porous support layer, transition layer, and membrane layer are all silicon carbide materials. Its filtration precision is microfiltration and ultrafiltration. The SIC membrane filtration system is a fluid separation process in the form of "cross-flow filtration". The raw material liquid flows at high speed in the membrane tube. Under the pressure drive, the clarified permeate containing small molecular components penetrates outward through the dense layer of the membrane in the vertical direction. The turbid concentrated liquid containing macromolecular components is intercepted, thereby achieving the purpose of clarification, separation, concentration and purification of the fluid.

Alternate name of SiC is Corundum or Moissanite, including black SiC and Green SiC. SiC crystal has two kinds of structures which are α-SiC & β-SiC. SiC material has features of stable chemical properties, high coefficient thermal conductivity, low coefficient of thermal expansion, excellent abrasion resistance performance, Moh's hardness 9.5 grade (only a little lower than diamond), high

temperature resistance, oxidation resistance. SiC is raw material of refractory, abrasive, metallurgy, photovoltaic industry.

SiC Ceramic Microfiltration & Ultrafiltration Membrane is sintered through recrystallization technique in high temperature of 2400℃. The raw material Silicon Carbide have features of high hardness and high strength.

| Name | SIC membrane | Polymer membrane | Al2O3 ceramic membrane | Metal membrane |

| carrier material | 100%SIC | Polymer Materials | oxide | The golden mantis is supported by the snail hinge and the duel. |

| Membrane filter material | 100%SIC | PSIPVCIPAN\PVDFIPES | oxide | Oxide loading |

| Hardness | high | Low | high | high |

| Operating pressure | 1-2 bar | 1-2 bar | 3-4bar | 4-6bar |

| Pure water flux | 3~4m3/m2.h | 0.08~0.12m3/m2.h | 0.25~3m3/m2.h | 0.25~0.5m3/m2.h |

| Temperature resistance | 800 degrees (air) | <40 degrees | <300 degrees | <300 degrees |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us