Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

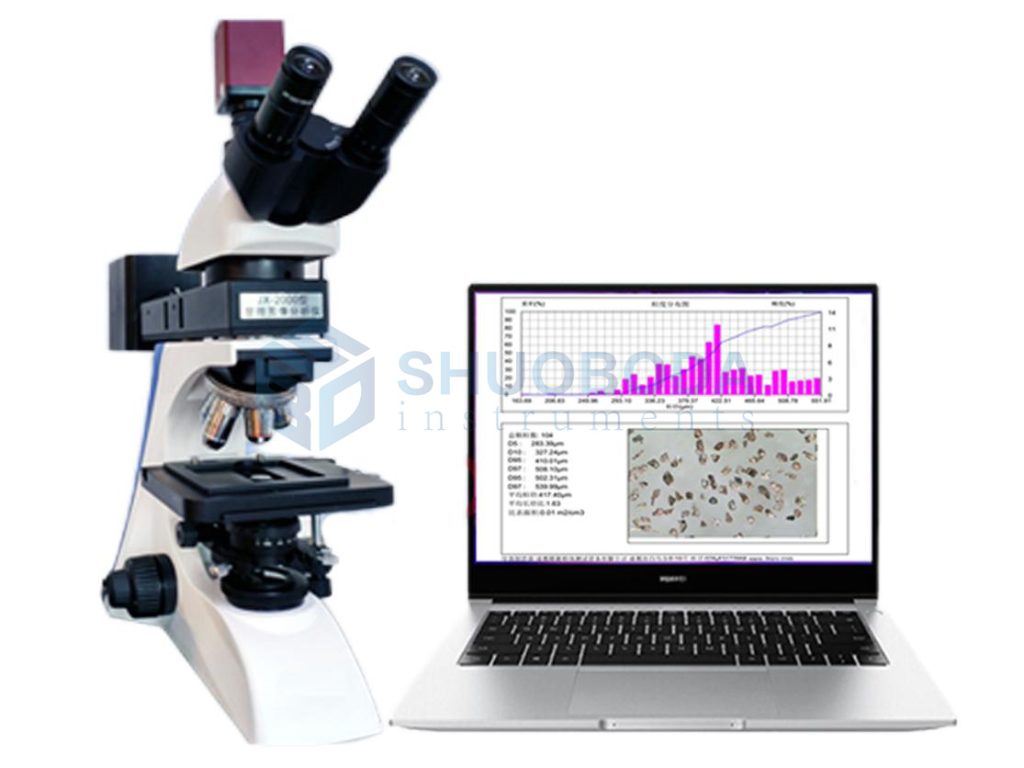

The PIA-3000B Particle Image Analyzer consists of an optical microscope, a digital CCD camera, image processing and analysis software, a computer, a printer, etc. Because powders have different shapes, when testing with a laser particle size analyzer, a particle image analyzer can be used to more accurately visualize the particle size and shape and control product quality.

1. Various mineral powders such as diamond, silicon carbide, wollastonite, quartz powder, barium sulfate, graphite, lithium cobalt oxide, boron carbide, white corundum, cerium oxide mica powder, carbon powder, metal powder, etc.

2. Various powders or slurries such as glass beads, cement, medicines, food, pigments, dust, pesticides, catalysts, etc.

3. It is also used to verify other means and methods of particle size testing.

| Model | PIA-3000B |

| Analysis items | Particle size distribution, aspect ratio distribution, circularity distribution, etc. |

| Test range | 0.5~3000μm |

| Magnification | ≤4000 times |

| Optical magnification | 1600 times |

| Resolution | ≥0.1μm |

| Microscope | Transflective microscope (optional domestic/metallographic/imported) |

| Digital camera (CCD) | 3 million pixels/5 million pixels |

| Eyepiece | 10X, 16X |

| Objective lens | 5X, 10X, 20X, 50X, 100X |

| Scale scale | 10μm |

| Software operating environment | Windows7 32-bit |

| Interface mode | USB interface for high-speed and stable transmission |

1. Software analysis and processing functions

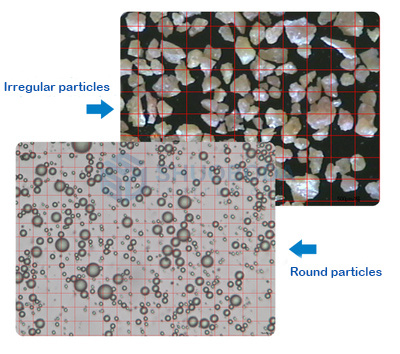

The image analysis software can directly observe the particle morphology under the microscope and collect pictures. The pictures can be saved in JPG or BMP format; the image height, width, resolution, etc. can be adjusted after the software collects the image. The corresponding ruler or grid can be set according to the images collected by the objective lens of different magnifications to intuitively observe the particle size.

Freely switch the particle size unit. The ruler supports a variety of unit options and can be freely switched between microns and millimeters, centimeters, and inches, which is convenient for further processing of small and large particles.

2. Image analysis and processing

Tone processing: grayscale, tone adjustment, brightness, contrast adjustment;

Image correction: horizontal mirror, vertical mirror, 90 degrees (counterclockwise), 90 degrees (clockwise), rotation, zoom in, zoom out, arbitrary scaling, etc.;

Measurement unit: micrometer, millimeter, centimeter, inch (optional);

Image enhancement: contrast balance, expansion, corrosion, etc.;

mage processing: image sharpening, edge smoothing, binarization, area filtering, boundary filtering, analysis target erasure, hole filling, manual erasure, manual connection, particle property viewing, etc.;

3. Multiple images can be batch processed to increase the number of particles, improve the representativeness of the sample, and make the processing results more accurate, true and reliable.

4. The software is powerful and can design special software for abrasives, wollastonite, etc. according to the special requirements of the industry.

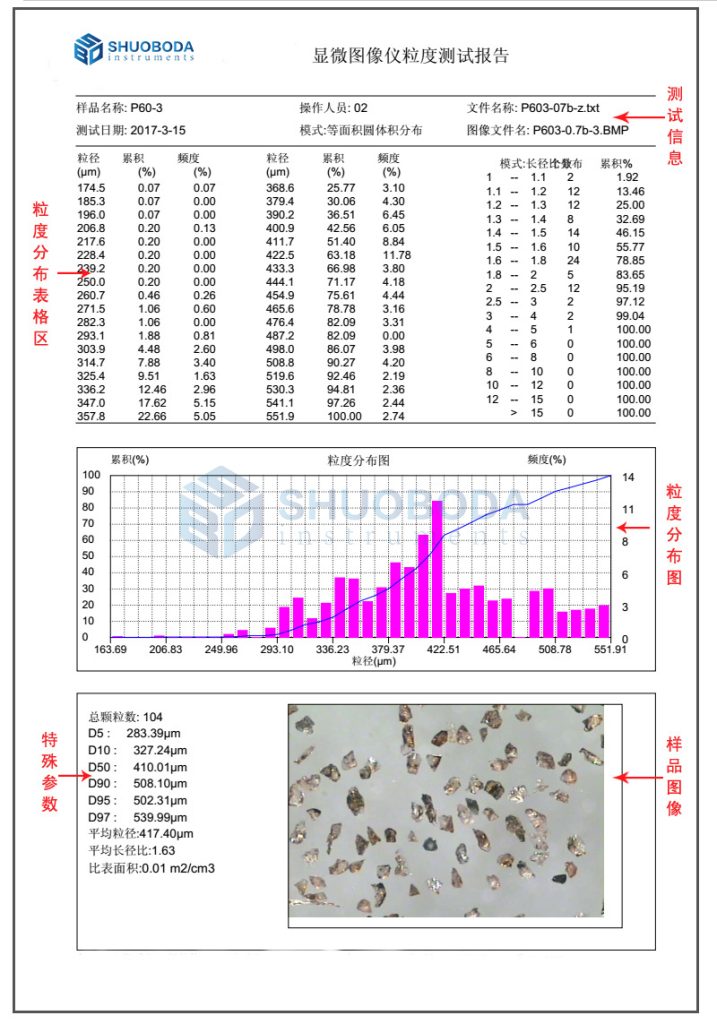

5. Report output

After processing the image, the computer automatically counts the number of particles, area, perimeter, volume, diameter, circularity distribution, aspect ratio distribution, particle size distribution data, as well as characteristic values such as D10, D50, D90, D97, average particle size, and surface area.

The sample color thumbnail can be displayed in the report, and multiple information such as sample name, test unit, and dispersion medium can be entered into the report header. Multiple report formats can be selected.

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us