Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

PRODUCT MODEL: MDP-45

Category: Media Processing

Tag: Automated Culture Media Preparator

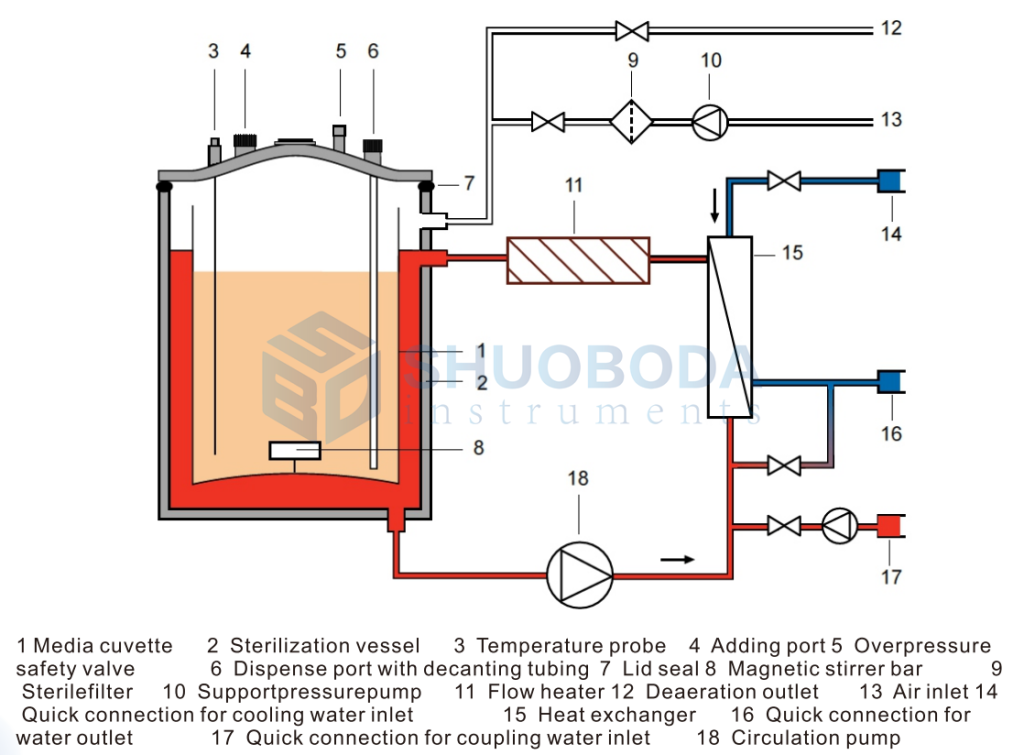

MDP-45 Automated Petri Dish Medium Preparators come with flexible automated media reader is flexible – ready to allow you to quickly sterilize and prepare high quality media. This minimizes the space required to store the finished petri dish, eliminates the management of the petri dish storage, and ensures high quality media uniformity. It can quickly and gently sterilize the medium and accurately monitor and control the time, temperature, pressure and other parameters in the sterilization process, so as to ensure that all sterilized products have the same high quality, its intuitive graphical interface and the programming function makes it easy for everyone to operate the instrument.

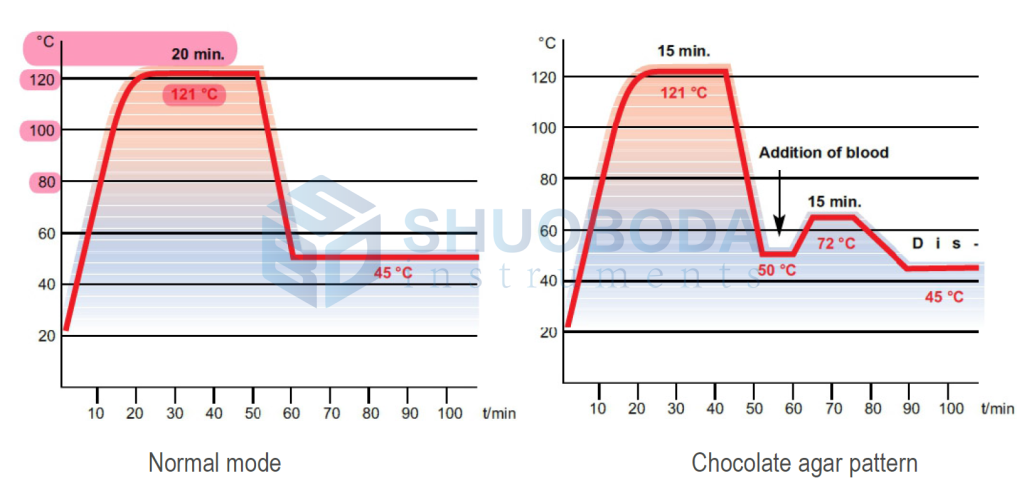

MDP-45 preparator can be quickly prepared for sterilization, placed in a sterilizer, and filled with water in a “water jacket system” (sleeve water between the sterilizer and the sterilizer cavity for efficient heat transfer), added to the medium Raw materials, ready to start the sterilization process. The medium can be suspended and dissolved directly in MDP-45 preparator. Strong magnetic stirring ensures uniformity of mixing in the inner chamber and prevents condensation. The medium can be pre-dissolved in WATER BATH mode prior to sterilization. At the same time, an intuitive graphical interface makes it easy to operate without specially trained personnel. Users can customize multiple sterilization procedures, such as sterilization temperature, time, and dispensing temperature.

| MODEL | MDP-45 |

| Load capacity | 47L, cavity 62L |

| Cavity size | 400 mmx 480mm |

| Pail size | 380mm x 440mm |

| Sterilization temperature | 90-135℃, design temperature 147℃ |

| Packing temperature | 35-80℃ |

| Water bath temperature | 0-100℃ |

| Temperature accuracy | 0.1℃ |

| Temperature offset | 1℃ |

| Time setting accuracy | 1 minute |

| Maximum working pressure | 2.5bar |

| Design pressure | 3.5bar |

| Sterilized water in the cavity | deionized pure water, can automatically enter the water (pressure not less than 1bar), and alarm for high and low water levels |

| Cooling water interface | 2 points inner wire diameter 12 pagoda joint |

| Circulating water | the pressure is not less than 1bar tap water |

| Drainage interface | 2 points inner wire diameter 12 pagoda joint |

| Sterilizer material | S31603 |

| Packing ports | two, which can adapt to various packing requirements, and one of them can also be used for aseptic addition of materials |

| Dispensing hose | inner diameter 6mm, thickness 2mm |

| Material adding port | diameter 32mm |

| Stirring | strong magnetic stirring, the speed is 0-240rpm, adjustable |

| Cooling system | supplementary pressure water cooling system can maintain the cavity pressure during rapid cooling |

| Safety measures | Unique cover lock design, dual control of temperature and pressure. If the temperature is greater than 80°C and the pressure is greater than 50mbar, the outer cover cannot be opened and it will automatically lock; if the pressure is greater than 50mbar, the upper cover cannot be opened and it will automatically lock to ensure that the cover will not be opened accidentally during operation; over-temperature protection is 130°C, if the temperature exceeds the set temperature 2.5℃ automatic warning, over-temperature automatic power-off; safety valve opening pressure 1.7bar, built-in safety valve will not accidentally injure the operator. |

| Temperature sensor | flexible PT-100 temperature probe in the medium preparation chamber and place it anywhere in the chamber |

| Heating power | 15KW |

| Power requirements | 3×380-420V, 50/60Hz, 40A |

| Dimensions | height 920mmx length 670mmx width 790mm |

| Net weight | 160kg |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us