Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

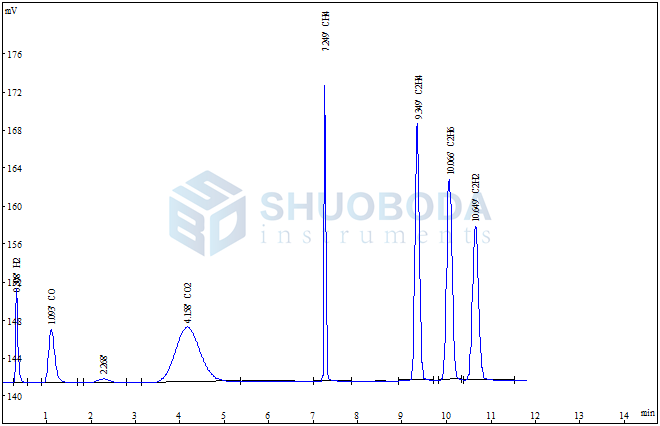

GC2003 is a special gas chromatograph for dissolved gas analysis of transformer oil (insulating oil). The analysis of dissolved gases (H2, CO, CO2, CH4, C2H4, C2H6, C2H2) adopts a single injection, dual-column parallel connection, and three-detector detection solution. If you also need to detect the contents of O2 and N2, you can choose the nine-component configuration plan.

| Components | H2 | CO | CO2 | CH4 | C2H4 | C2H6 | C2H2 |

| Minimum concentration μL/L | 2 | 0.5 | 0.5 | 0.05 | 0.05 | 0.05 | 0.05 |

| Detector | Sensitivity/detection limit | Baseline noise | Baseline drift | linear range | Stable time |

| TCD | ≥3500 mv·ml/mg(benzene) | ≤10μv | ≤60μv/30min | 105 | ≤1h |

| FID | 1.0 pg/s(n-C16) | ≤5μv | ≤50μv/30min | 107 | ≤30min |

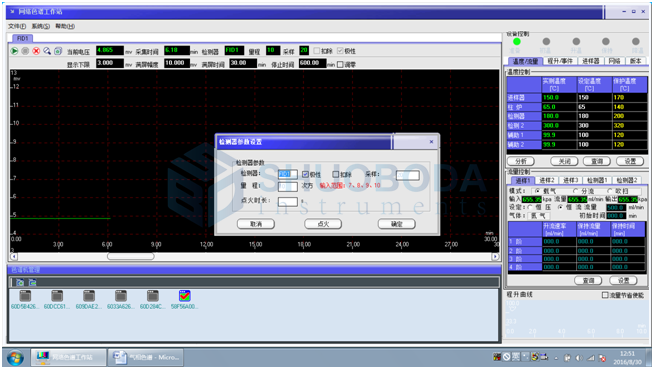

4.1 The human-computer interaction interface of the 5.7-inch color touch screen is intuitive and easy to understand;

4.2. Full microcomputer control system, a single computer can control up to 253 chromatographs, with 7-channel temperature control; 8-channel external event time program;

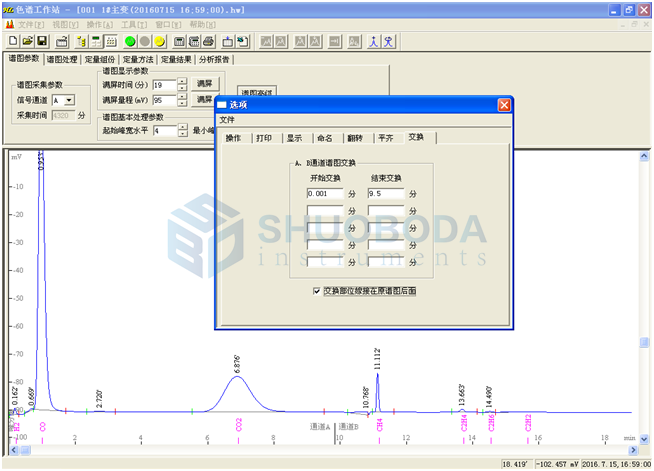

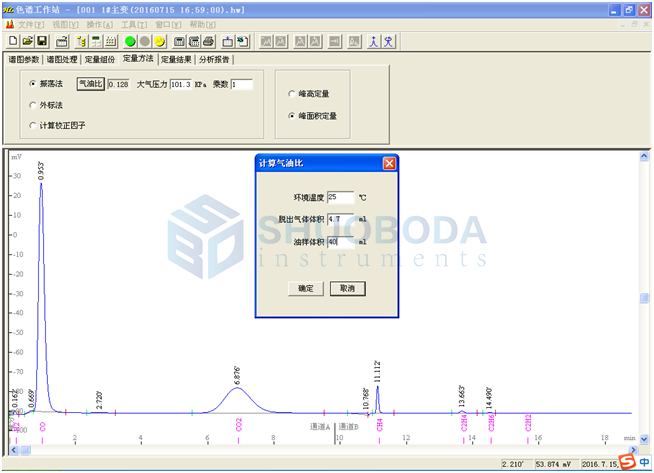

4.3. The built-in special workstation for dissolved gas analysis in power transformer oil can integrate the effective parts of multi-channel spectra to facilitate spectral processing. It can make a trend curve of the content of each gas component changing over time at the same sampling point, and the report will automatically give three Ratio coding as well as fault properties and typical examples;

4.4. The instrument adopts RJ45 network cable interface, which makes signal output and control acquisition simple and convenient. It can realize remote control of the instrument and remote data transmission, processing and supervision. Can be connected to unit supervisors and superior supervisors to facilitate supervision by supervisors;

4.5. Equipped with a dedicated independent balance gas intake port, gas oscillation will not affect analysis.

4.6. Using the anti-pollution composite chromatography column technology specially used for transformer oil, the service life of the chromatography column is longer.

4.7. The large-capacity column oven is equipped with an automatic rear door, which can carry out 8-step program temperature rise, and the column oven has a near room temperature control function (5℃ above room temperature);

4.8. It has a fault self-diagnosis function, which can display the location and nature of the fault at any time; it has an over-temperature protection function, and the heating will automatically stop if the temperature of any path exceeds the set temperature.

5.1. Instrument temperature control parameters

Number of temperature control interfaces: 7 channels

Temperature control range: room temperature +5℃~400℃

Temperature control accuracy/stability: ≤0.5%

Display accuracy: 0.1℃

Programmed temperature rise:

Programmed temperature rise steps: 8 steps

Programmed heating rate: 0~39.9℃/min (adjustment increment 0.1℃/min)

Repeatability of programmed temperature rise: ≤0.5%Cooling rate: <5min (from 300℃ to 50℃) (automatic rear door opening)

5.2. Number of external event interfaces: 8 channels

5.3. Column box volume: 180×280×280mm (depth×width×height)

5.4. Host size: 650×480×500mm (length×width×height)

5.5. Instrument weight: about 53kg

5.6. Power: about 2000W

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us