Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

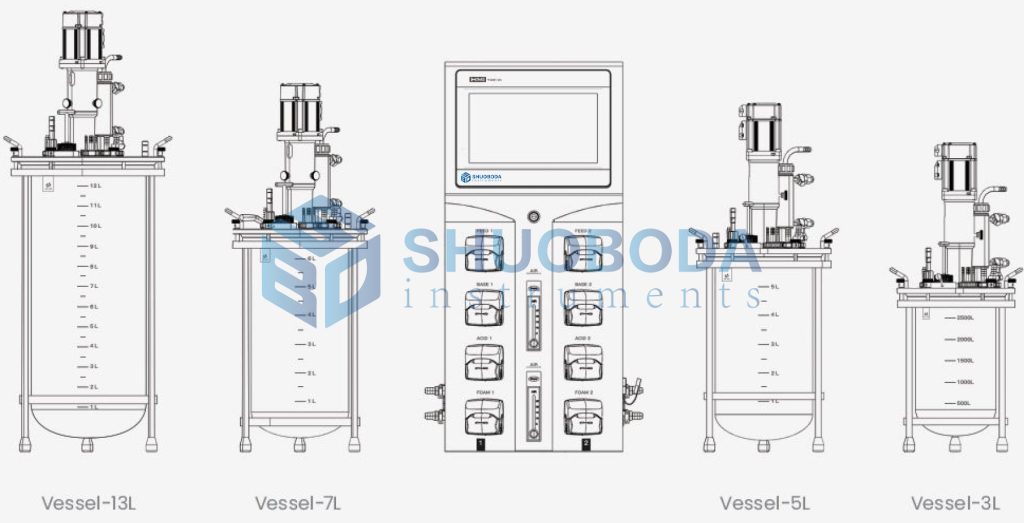

PRODUCT MODEL: FMT-T Series

Category: Glass Bioreactor, Parallel Bioreactor

Tags: Multi- Parallel Bioreactor Fermenter, bioreactor, Fermenter, Glass Bioreactor, lab fermenter

FMT-T laboratory duplex fermenter is a special series from shuoboda for laboratory users with two parallel fermenters. The product adopts a system strategy of one main unit controlling two fermenters. Users can choose to use dual control or single vessel. FMT-T duplex fermenter is a stable and useful laboratory equipment with excellent quality and high-cost performance.

FMT-T series double fermenter adopts integrated host design. 10-inch high-end touch screen. which can control two 1L~15L. class fermenters at the same time or separately. It adopts four sets of peristaltic pumps and variable speed peristaltic pump design. Siemens PLC is the control core, common hardware and consumables with FMT series.

FMT-T series is an experimental equipment for laboratory users to perform simultaneous fermentation. The product adopts a system strategy of one main unit controlling two fermenters, and the glass vessel contain 3L, 5L, 7 and 13L, supporting free combination and matching. Users can choose to use dual control or single vessel. which is extremely flexible for users with different needs and scenarios.

| Comparable to imported manufacturing process tanks Derived from Sartorius and Applinkon tank design ideas, replaceableStable air tightness, convenient and quick disassembly and assembly mechanism, and convenient laboratory operationMade of overall AISI 316L stainless steel, precision ground and electrolytic polished, the overall manufacturing process is comparable to the same imported products from the United States and abroad. |

| High-end configuration of the entire series Siemens SIMATIC-Smart series original processorHigh-precision flip-top peristaltic pump and original imported componentsMain power parts such as motors, insulation blankets, and peristaltic pumps all use 24V low-voltage DCEquipped with 8 peristaltic pumps, the functions can be freely defined as acid addition, alkali addition, defoaming, and feeding. |

| Powerful FMT-M2 Controller Equipped with a 10-inch advanced touch screen and using Bus communication to achieve dual controlThe main screen displays the main operating parameters of 2 sets of parallel tanks at the same time, which can control a single tank or in parallel.Built-in SD-Control V2.2 control software, which can implement online monitoring, recording, tracking and other functionsCan be externally connected to OPC XML DA via Ethernet data communication |

| The second-generation graphical interface parallel control system Brand new second generation graphical interface, leading industry designComfortable human-computer interaction experience, simple and convenient operation, and supports external expansionAchieve data visualization and information graphics, and process changes can be seen at a glanceRefined design, distinct color divisions, and perfect functional |

| No. | Item | Specifications |

| 1 | Vessel | Full volume: 3L, 5L, 7L, 10L,13L,15L optional, 2 groups configured, can be freely combinedLiquid filling capacity: Max 80%Design pressure: Max 0.15MpaGlass tank: high temperature resistant borosilicate glassCan lid: AISI 316L stainless steel, electrolytic polishedTank cover: air inlet, four-in-one feeding port, temperature sleeve, cooling coil, pH/DO electrode port, feed port, spare port, tail gas condenser (removable), harvest tube, defoaming Electrode port |

| 2 | Stirring system | 2 high-precision and low-noise servo motors, with low operating noise and jitter, and more stable operationSpeed: 0~1000rpm±1rpmInnovative inorganic seal design, the first in the industry, makes the mixing system cleaner and more hygienicNo installation guidance, no installation and maintenance, just put into useIntelligent sequence control, which can adjust mixing parameters within a customized time period |

| 3 | Air inlet system | Air intake: Air; quick release structure2 imported glass rotor flowmeters, optional MFCAnnular gas distributor, optional microporous bubble distributorGeneral ventilation is divided into 2 channels into 2 groups of fermentation tanks, and is equipped with a 2-channel air intake system |

| 4 | pH detection and control system | Configure 2 sets of pH modulesRange: 0.00~14.00 pH, accuracy: ±0.02Sterilization temperature: 0~140℃Control: SD-K integrated transmitter, with filter, signal isolator, RS-485 communicationAssociation settings: pH is automatically associated with the acid-base pump, the dead zone is customized, and the accuracy can reach ±0.02Intelligent sequence control, which can adjust pH parameters within a customized time period |

| 5 | DO detection and control system | Configure 2 groups of DO modulesRange: 0~100% O₂ saturation, accuracy: ±1%Sterilization temperature: 0~140℃Control: SD-K integrated transmitter, with filter, signal isolator, RS-485 communicationMulti-stage cascade control of DO, stirring, and feeding ensures sufficient gas output during the experiment.Satisfy custom time period DO parameter control |

| 6 | Temperature Control System | Dual temperature control means of electric heating and cooling water for thermal insulation blanket24V safety voltageTemperature control range cooling water +5℃~65℃±0.1℃Temperature sensor: imported PT100 platinum electrode (high temperature resistant quick release form)The cold-water module is integrated with the FMT-M2 controller, communicates with the host PLC, and controls the on-off of the solenoid valve.The cold-water connector adopts imported self-locking quick interface, and the interface contains a self-locking valve. |

| 7 | Peristaltic pump | Equipped with 8-channel peristaltic pump, the functions can be freely defined as acid addition, alkali addition, defoaming, and feeding.High-precision variable-speed flip-top pump, quick connectionApplicable to multiple specifications of silicone tubes, the flow rate can reach up to 560.04mL/minThe peristaltic pump can realize functions such as instantaneous flow, cumulative flow, speed adjustment, manual and automatic switching operation, and associated PID adjustment.Feeding system supports one-time, on-time, index, and equation feedingWith intelligent sequence control, feeding parameters can be adjusted at any time as needed. |

| 8 | Defoaming system | Equipped with 2 sets of mechanical defoaming stirring paddlesDefoaming agent: peristaltic pump can be added manually or automaticallyHighly sensitive defoaming electrode |

| 9 | sampling | Sterile sampling system, sterilizable by high temperature and high pressureThe negative pressure design of the syringe eliminates the worry of bacterial contamination during the sampling process.Dual design, users can also use traditional flame inoculation method to inoculate |

| 10 | FMT-M Controller SD-Control v2.2 control system | 10-inch HMI touch screen, brightness >350cd/㎡Siemens SIMATIC-Smart series original processorLow-voltage electrical appliances use internationally renowned brands such as SchneiderEmbedded SD-Control V2.2 embedded control software configuration to achieve full local operationDC, pH, DO, T, FOA, etc. can be controlled automatically and manuallyRPM, TEM, pH, DO curve display function, historical data recording and USB exportMeta-Tri® audit trail, the exclusive research and development system automatically stores operation records, and the experimental process can be tracedReal-time protection of experimental data, advanced permissions to restrict export and deletion, and prevent data leakageCan be externally connected to OPC XML DA via Ethernet data communicationIn addition to the standard configuration, users are supported to add: 2~4 channels of ventilation, balance, exhaust gas analysis, external peristaltic pump, etc. |

| 11 | power supply | Input: AC110~240v/1.2kwOutput: Motor, thermal blanket, peristaltic pump and other power parts use 24V safety voltage |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us