Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

PRODUCT MODEL: FMT-L Series

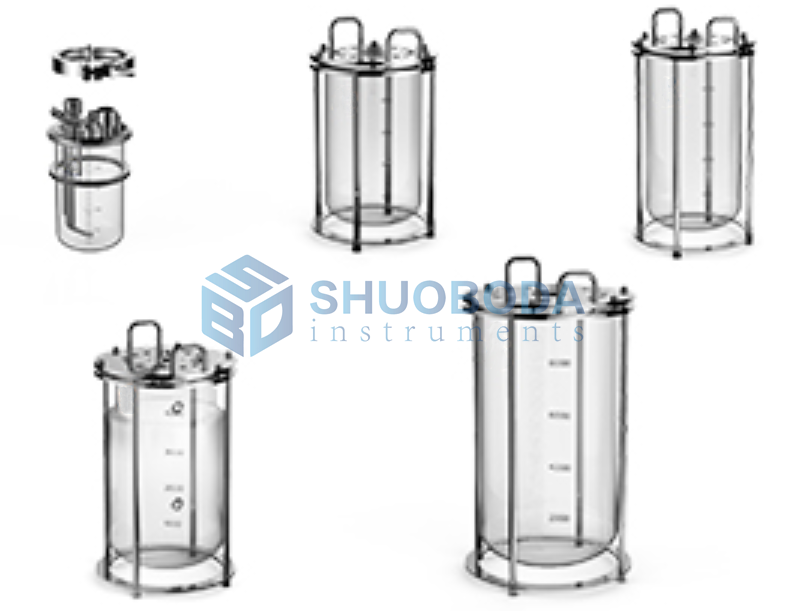

Category: Glass Bioreactor

Tags: bioreactor, Fermenter, Glass Bioreactor, lab fermenter

FMT-L series Laboratory Glass Fermenter Bioreactor is a fermentation unit for laboratory research that can be used to culture microorganisms or bacteria. The device can be set up by executing the user-defined parameter settings specified in the menu. The measurement and control system allows online measurement, control and evaluation of process parameters (e.g. temperature, pH and dissolved oxygen values) and independent monitoring of microorganisms or bacteria in each culture tank.

| Excellent, sophisticated design brings the industry's most outstanding tank system Abandon the thread design, the maximum load can reduce the thickness of the can lid, reaching an amazing 6mmThe opening adopts modular quick release design to reduce dead angle and eliminate bacteriaAdapt to multi-brand monitoring equipment, post-modification and maintenance can be realized through conversion parts |

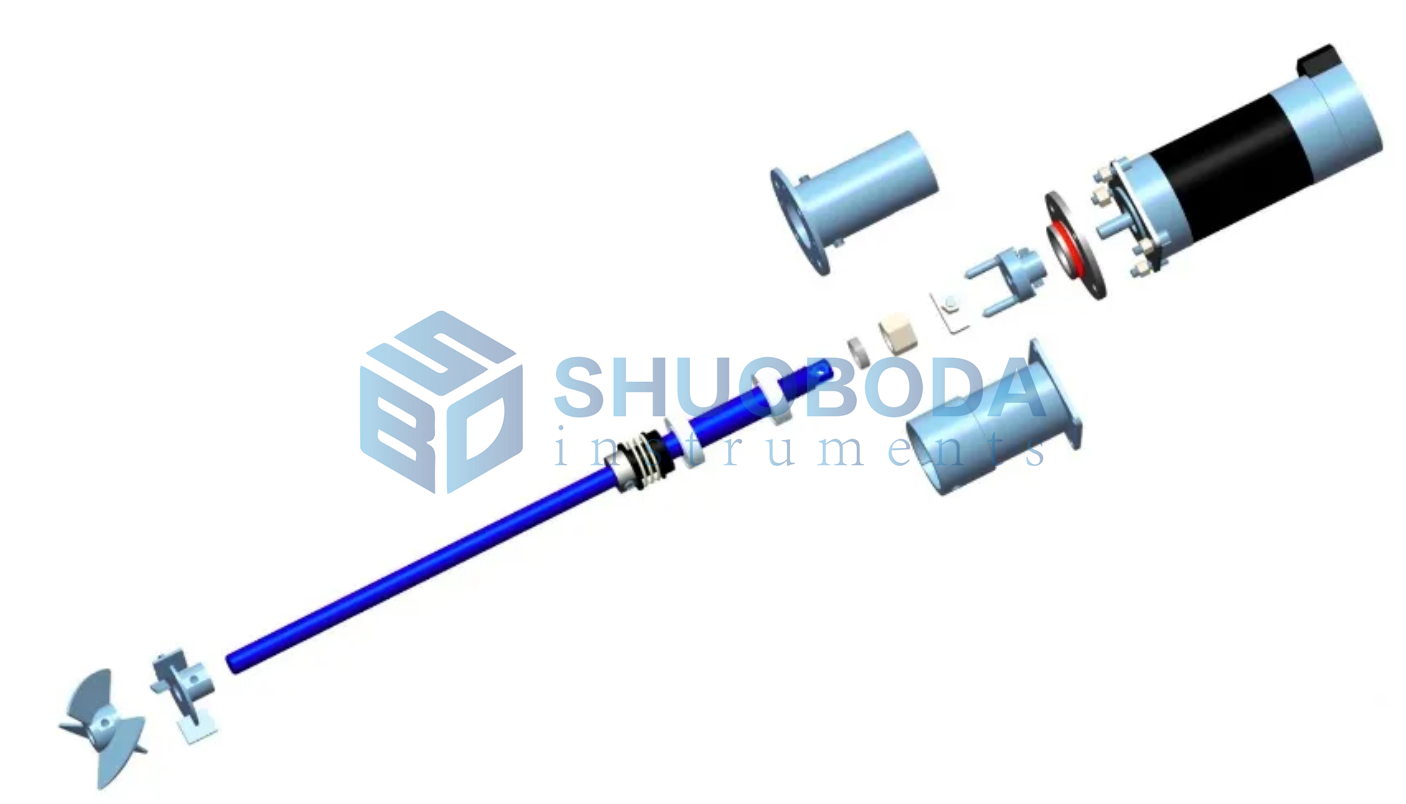

| Advanced mixing system eliminates tank contamination High-quality mechanical seals eliminate a trace of pollution from machinery1000+ times of mixing and balancing test to make the stirring stable and controllableThe self-developed coupling realizes quick loading and quick release of the motor, which is convenient and simple |

| The best FMT-controller design ever since Simple, easy to use, and scalableIndustry's smallest volume FMT-controller, L*W*H: 410*215*435Equipped with a 7.0-inch capacitive touch screen, multi-touch, can be connected to the computer control section to achieve joint controlEquipped with a common quick release interface, 3 peristaltic pumps, support for external expansionBuilt-in SD-Control control software for online monitoring, recording, and curve displayRemote control with computer configuration software SD-Control |

| From the core technology of Germany, a strong R & D team The core R&D team comes from the German company fermenter team, stable and reliable technical supportStrong corporate philosophy to support the excellence of our productsProduct design is comparable to imported fermentation tanks such as NBS and ApplinkonR & D team experienced 4000L bioreactor design experience |

| No. | Item | Specifications |

| 1 | Tank body | 3L, 5L, 10L ,15L optionalMax liquid load capacity:80%Design pressure:Max 0.2Mpa Material: tank: high temperature borosilicate glass, can lid: AISI 316L stainless steel |

| 2 | Mixing system | High-precision brushless AC servo motor, special mechanical sealSpeed: 0 ~ 1200 rpm ± 1 rpmFifteen-stage speed regulation, the program sets the required speed at each stage, professionally buildsSpecial mixing paddle: single layer inclined blade mixing paddle, flat blade mixing paddle, can replace the specified mixing paddle |

| 3 | Intake system | Intake: air; quick release structureImported U.S. DYAIR brand glass rotor flowmeter, optional electromagnetic flowmeterAnnular gas distributor |

| 4 | pH | Range: 2.00 to 12.00 pHAccuracy: ±0.02Ambient temperature Operating temperature: 0~100°CSterilization temperature: 0 ~ 130 ° CControl: SD-K integrated transmitter |

| 5 | DO2 | Range: 0 to 200%Accuracy: ±0.1%Ambient temperature Operating temperature: 0~100°CSterilization temperature: 0 ~ 130 ° CControl: SD-K integrated transmitter |

| 6 | Temperature Control System | Insulation blanket electric heating method, water bath temperature control mode optionalHeating power: 300W, 24V safe voltageTemperature control range: Cooling water temperature +5~65℃Temperature sensor: PT100 platinum electrode (high temperature quick release form) |

| 7 | Peristaltic pump | ANTIFOAM/FEED/ACID-BASE 3 peristaltic pumpsLONGER original variable speed peristaltic pumpControl can be set to ml/min, or 0 to 100% proportional control |

| 8 | Defoaming system | Mechanical defoaming paddle: compression mechanical defoaming pulp with rake.Defoamer: peristaltic pump flow addedHighly sensitive defoaming electrode |

| 9 | sampling | Sterile sampling system, can be autoclavedSyringe negative pressure design, get rid of the distress of the bacteria in the sampling processDual design, users can also use traditional flame inoculation methods |

| 10 | FMT controller, SD-Control software | 7-inch advanced capacitive touch screen, multi-touch operationController: Original Siemens PLC controllerAll parameters are displayed, controlled and edited onlineRpm, T, pH, DO2 curve display function, historical data recording and exportSoftware modularity: powerful software modular design supports user customization, and can be customized according to user-specified requirements. |

| 11 | power supply | AC110~240v/0.8kw |

| 12 | Dimensions | Host:250mm*465mm*500mm (length*width*height) |

| model | FMT-3L | FMT-5L | FMT-10L | FMT-15L |

| Working volume | 1.2~2.4 L | 2~4 L | 4~8 L | 8~12 L |

| Borosilicate glass + 316L stainless steel | ● | ● | ● | ● |

| Mechanical stirring | ● | ● | ● | ● |

| Off-site sterilization | ● | ● | ● | ● |

| Heating blanket temperature control | ● | ● | ● | ● |

| Intake | Air | Air | Air | Air |

| temperature | R+C+P+MC | R+C+P+MC | R+C+P+MC | R+C+P+MC |

| Stir | R+C+P+MC | R+C+P+MC | R+C+P+MC | R+C+P+MC |

| pH | R+C+P+MC | R+C+P+MC | R+C+P+MC | R+C+P+MC |

| Defoaming | R+C+P+MC | R+C+P+MC | R+C+P+MC | R+C+P+MC |

| Ventilation | MC | MC | MC | MC |

| Tank pressure | MC | MC | MC | MC |

| DO2 | R+C+P | R+C+P | R+C+P | R+C+P |

| Feeding | MC+P | MC+P | MC+P | MC+P |

| Touch screen console | ● | ● | ● | ● |

| SD-Control control system | ● | ● | ● | ● |

R-Detection C-Automatic Control P-Program Control MC-Manual Control ● Standard

| No. | name | Model and description |

| 1 | FMT controller | Standard configuration: touch screen with embedded control software, gas mixer, flow meter, pH, DO2 electrode, temperature electrode, 3 peristaltic pumps and other accessories |

| 2 | 3L glass kit | Standard configuration: AC motor, can lid and accessories, mixing system, 3L glass tank, heating accessories |

| 3 | 5L glass kit | Standard configuration: AC motor, can lid and accessories, mixing system, 5L glass tank, heating accessories |

| 4 | 10L glass kit | Standard configuration: AC motor, can lid and accessories, mixing system, 10L glass tank, heating accessories |

| 5 | 15L glass kit | Standard configuration: AC motor, can lid and accessories, mixing system, 15L glass tank, heating accessories |

| 6 | Air compressor | Silent oil-free air compressor |

| No | Name | Brand |

| 1 | pH sensor | Switzerland HAMILTON |

| 2 | DO2 sensor | Switzerland HAMILTON |

| 3 | pH, DO2 signal line | Switzerland HAMILTON |

| 4 | Controller | Germany Siemens PLC SMART-200 series |

| 5 | touch screen | PID program controls independent intellectual property rights |

| 6 | Machinery Seal | United Kingdom JOHN CRANE |

| 7 | Peristaltic pump | LONGER original peristaltic pump |

| 8 | Feed bottle | Germany SCHOTT |

| 9 | Glass rotor flowmeter | United State DYAIR |

In order to let users better use our fermenter, we have developed a wide range of high-quality accessories for users to meet the needs of users in different industries and different conditions, users can choose the relevant accessories according to their own situation.

| SN | Name | Pictures | Description |

| FMT0001 | Computer client SD-Control |  | Communication process, stable, reliable, efficient and fast Equipped with computer configuration software SD-Control control software to provide advanced process control Support remote control, complex process control, integrated data and information management Full monitoring, display, 100% error free, zero delay |

| FMT0002 | High-precision circulating water machine B-Pelt 112 series |  | Peltier effect cooling Save water, the entire temperature control process only needs to cycle water volume Temperature range: 5 ° C ~ 75 ° C Accuracy ±0.1 °C |

| FMT0003 | Exhaust gas analyzer B-Gas 1.0 series |  | CO2: Non-dispersive infrared (NDIR) method O2: electrochemical method Resolution ±0.01% |

| FMT0004 | Laptop (dedicated) |  | Model: ThinkPad X260 Configuration: 12.5-inch screen, i5-6200U 8GB 192GB solid state drive Pre-installed SDS-Control control software for remote operation of fermenter Wireless network control module required |

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us