Professional Supplier of Laboratory Scientific Instruments

Professional Supplier of Laboratory Scientific Instruments

PRODUCT MODEL: FMT-C Series

Category: Glass Bioreactor, Parallel Bioreactor

Tags: Multi- Parallel Bioreactor Fermenter

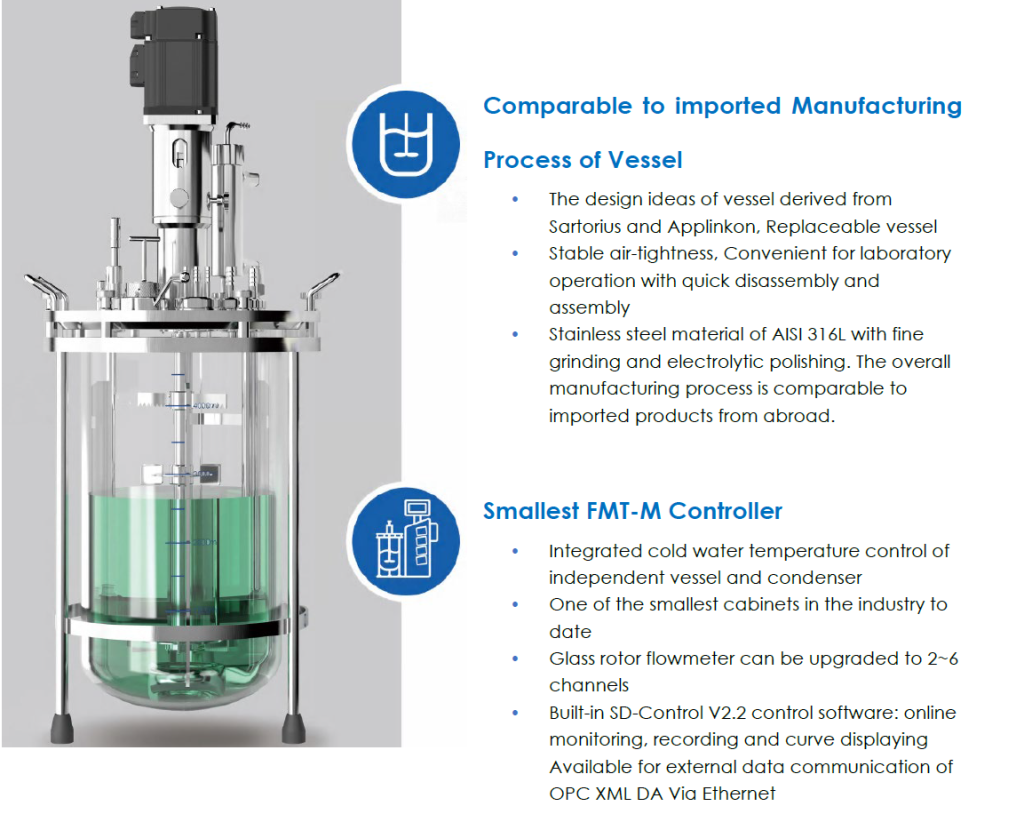

Fermenter FMT-C is a classic and standard system developed by SHUOBODA for laboratory users. FMT-C adopts the latest design language and modular design concept, which is suitable for the design requirements of multiple working conditions in the laboratory. Absorbing foreign sophisticated design concepts, the product is small in size. And it is painted in classic white, with a novel appearance and a strong sense of design. The series adopts imported glass rotor flowmeter, high-precision flip pump and bus control communication method, which greatly improves the precision and stability of the equipment.

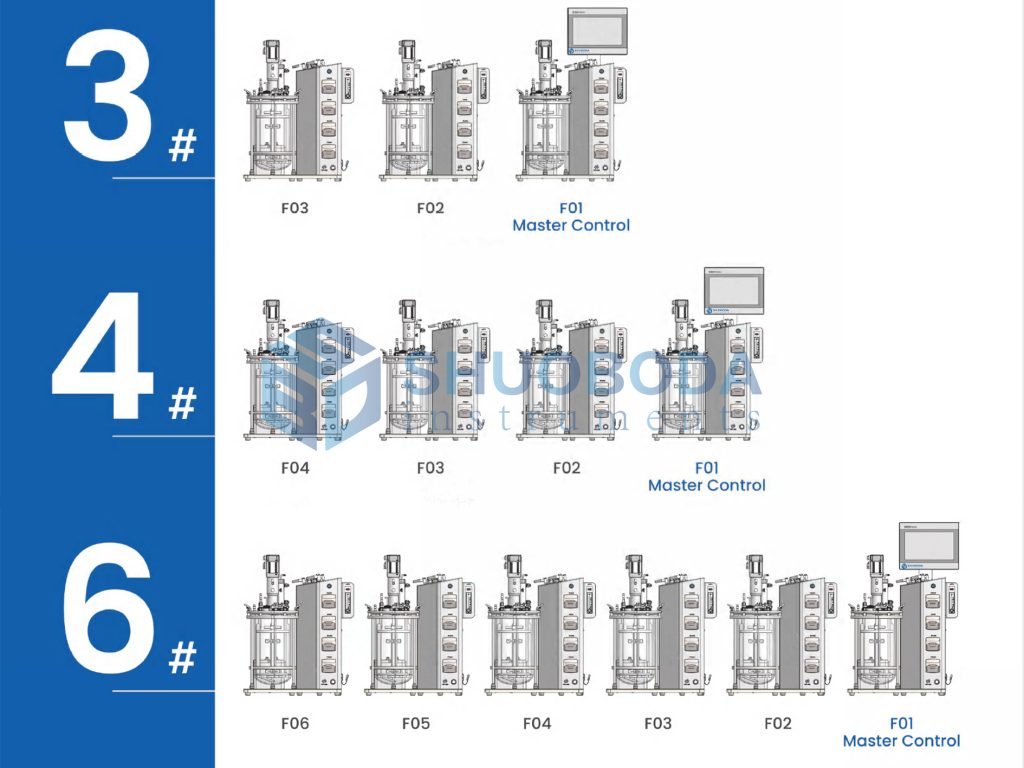

FMT-C adopts a deep modular process design language, an all-in-one structure of the vessel and the control unit, which makes overall space small. All kinds of weak wires are short and easy to install that can be quickly put into laboratory use. The compact size is especially friendly to female users. The modular design concept makes the FMT-C series the best presentation for multiple fermenters. By building blocks, it can easily realize double, triple, quadruple, quintuple, sextuple, and more combined vessel systems. The system can be used separately or in a unified way, which is very adaptable to users and scenarios with different needs.

Reliable components are the guarantee of product durability, the key components of FMT-C series are selected from domestic and foreign first-line brands. Our suppliers include: SEMENSMETTLER TOLEDO, SCHNEIDER ELECTRIC, Dwyer and other partners, Shuoboda truly accomplish quality control from the source.

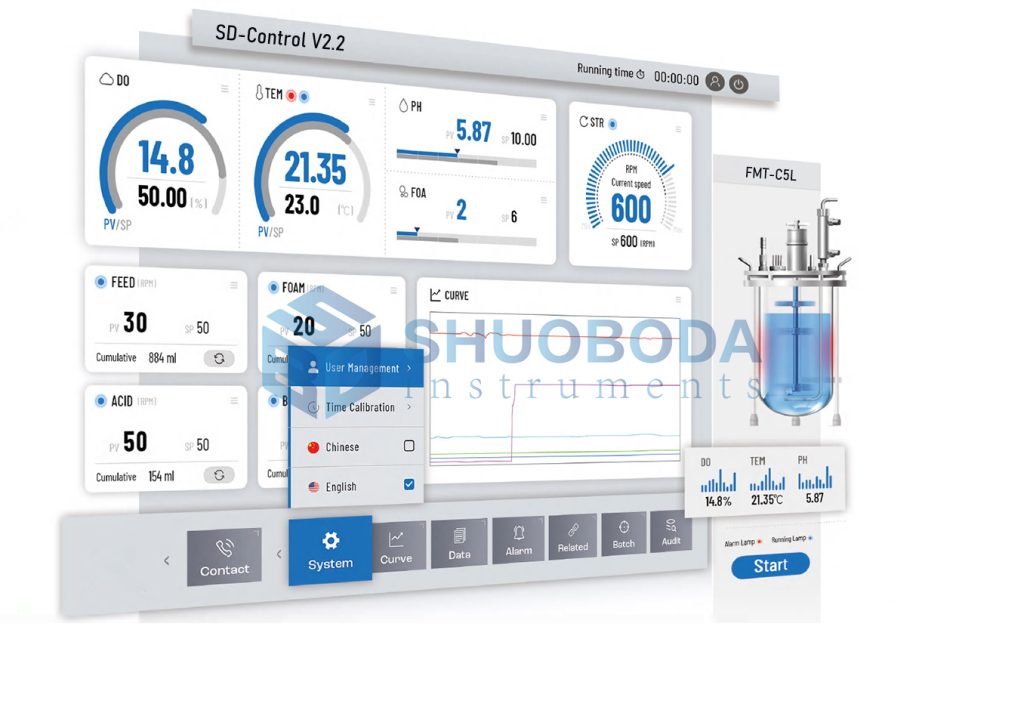

Since the creation of the first-generation GUI, Shuoboda has received many feedback from customerswith comments on aesthetics, ease of use, and more. In 2022, By the improvement of the usual GUI design features of the fermenter, Shuoboda works with a professional graphic design team combined with users' feedback to create the second-generation GUI with visual impact and practicality.

The second-generation GUI uses the latest dashboard design language to update the dynamicnumbers and graphics that users care about most. The user can observe the key data in thefermentation process at a glance by looking at the digital panel, without entering the secondary interface. Animations and dynamic presentations are made for graphics, which tend to be more flexible and intuitive. With the second-generation GUI, the user can grasp accurately the parameters and status of the fermentors, thus making rapid decisions.

GUI created by the professional design team has both a sense of design and practicability. The data and operations that users care about are convenient and easy to identify, enhancing familiarity and efficiency.

| No. | Item | Specifications | |

| Tank | |||

| 1 | Tank body | Full volume: 1L, 3L, 5L, 10L, 15L optional, no need to replace the controllerFilling volume: Max. 80%Design pressure: Max 0.15MpaTank cover port: air inlet, four-in-one feeding port, temperature sleeve, cooling coil, PH/DO electrode port, feed port, spare port, exhaust gas condenser (removable) | |

| Controller | |||

| 1 | Stirring system | Servo motor with high precision and low noise. Special mechanical sealRPM: 0~1200rpm ±1rpmFifteen sections speed: the program sets the required speed of each section | |

| 2 | Temperature Control System | Electric heating thermal blanket24V safe voltageTemperature control range: Cooling water+5°C~65°C ±0.1°CTemperature sensor: Imported PT100 platinum electrode (quick disassembly resistant to high temperature) | |

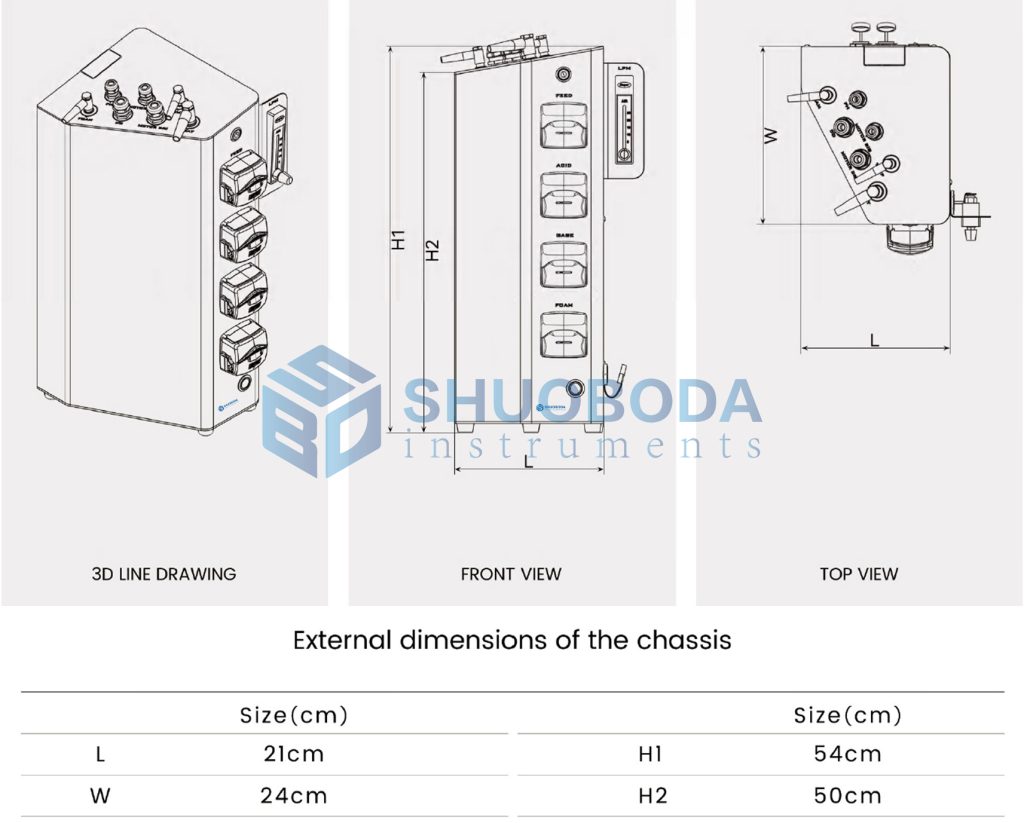

| 3 | Cold water module | Integrated FMT-M controller, independent moduleCommunication with host PLC, electromagnetic valve controls the flow-offCold water connector adopts imported self-locking quick coupling, which contains self-locking valve | |

| 4 | Defoaming system | Mechanical defoaming paddle with rake and compressionDefoamer: Flow addition by peristaltic pumpHigh-sensitive defoaming electrode | |

| 5 | pH detection and control system | Range: 0~14.00pH, precision: ±0.02Sterilization temperature: 0~130°CController: SD-K integrated transmitter with filter, signal isolator and RS-485 communication | |

| 6 | DO detection and control system | Range: 0~100% O2 sat, Precision: ±(1% of the numerical reading+6ppb)Sterilization temperature: 0~130°CController: HN-K integrated transmitter with filter, signal isolator and RS-485 communication | |

| 7 | FMT Controller SD-Control v2.2 control system | 10-inch HMI touch screen, brightness>350 cd/m²Siemens SIMATIC - Smart Series processorLow voltage electrical appliances use schneider and other international well-known brandsSD-Control V2.2 embedded control software configuration for full local operationFOA, pH, DO, T can realize automatic and manual controlCurve display, historical data records and USB export functions of RPM, pH, DO, TExtensible: glass rotor flowmeter of 2~4channels, balance, external peristaltic pump, etc.External OPC XML DA via Ethernet data communication | |

| 8 | Multi fermenters extension | Multiple system expansion of 2-8 fermentorsSLocal HMI centralized controlMulti-fermentors adopt network cable bus communication mode | |

| Other info | |||

| 1 | Air inlet system | Air inlet: Air, Quick disassembly structureImported glass rotor flowmeterAnnular gas distributor, Optional microporous bubble distributor | |

| 2 | sampling | Sterile sampling system: autoclave sterilizationSyringe negative pressure design: remove bacteria contamination during samplingDual design: users can also use traditional flame inoculation method | |

| 3 | power supply | Input: AC110 ~ 240v/1.2kwOutput: Motors, thermal blankets, peristaltic pumps and other power components use 24Vsafe voltage | |

| 4 | Size(L*W*H) | Dimensions after assembly: 295*327*763mm | |

The FMT-C series follows the concept of deft design. After calculating the internal structure in detail, engineers reduce the size of the chassis by more than 20% to achieve a compact and comprehensive characteristic. The height of the main control box is only 54cm, with a modular design, it is an integrated structure with the tank body, and the overall occupying space is small which is in line with the market. Compared with other laboratory fermenters, the volume advantage is obvious.

Exquisite and compact at the same time, taking into account the powerful functions. The whole series adopts imported glass rotor flowmeter, convenient and quick clamshell peristaltic pump and bus control the communication mode, which greatly improves the precision and stability of the equipment.

FMT-C has been deeply integrated with the modular design concept from the beginning of its design. lts compact size makes it easy to implement the multiple fermenters strategy. The most advanced BUS wiring system is also adopted in the process of automation research and development.

Each product of FMT-C is equipped with a local touch screen HMl which is an independent fermenter for standalone use. And apart from HMl, it is a host system matched on site. Multiple fermenters can be connected to a local HM. which can realize multi-connection. The multi-use scenarios and adaptability of customers have never been easier.

Experienced service team and strong production support team provide client worry-free order service.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.

Contact Us